The development trends in casting technology are primarily reflected in green environmental protection, digitalization and intelligence, and the application of advanced processes. Specifically, they are as follows:

1. Green Environmental Protection

Reducing Pollutant Emissions: With increasing environmental protection requirements, the foundry industry will adopt new, low-pollution raw and auxiliary materials, optimize production processes, and improve energy efficiency to reduce particulate matter, exhaust gas, wastewater, and other pollutant emissions during the casting process. For example, the guiding opinions issued by the Ministry of Industry and Information Technology and three other departments propose that by 2025, particulate matter emissions from the foundry industry will be reduced by more than 30% compared to 2020 levels.

Improving Resource Utilization: Promoting the application of foundry waste sand recycling and treatment technologies and the recycling and utilization of scrap metals will increase material recovery rates and reduce resource consumption. The goal is to achieve an annual recycling rate of over 8 million tons of foundry waste sand by 2025.

2. Digitalization and Intelligence

Digital Design and Simulation: By introducing advanced computer-aided design (CAD) and computer-aided engineering (CAE) systems, digital simulation of the casting process can be performed to optimize process parameters, predict and resolve potential quality issues, and improve the accuracy and reliability of process design. Intelligent Production: Leveraging technologies such as the Industrial Internet, big data, and artificial intelligence, we can achieve intelligent control of casting equipment and automated monitoring of the production process. For example, we can establish a platform for collecting equipment operation and energy consumption data to enable intelligent analysis of equipment maintenance and energy consumption; and establish a production control platform to enable monitoring and early warning, precise planning, lean and low-carbon production, and visual oversight.

3D Printing Technology Application: The integration of 3D printing and casting presents a key opportunity for green upgrades in the foundry industry. For example, the “3D+” casting process, based on 3DP printing production technology, can enhance rapid and high-end manufacturing capabilities, shorten production cycles, increase production capacity, and reduce scrap rates.

3. Development of Advanced Processes and Equipment

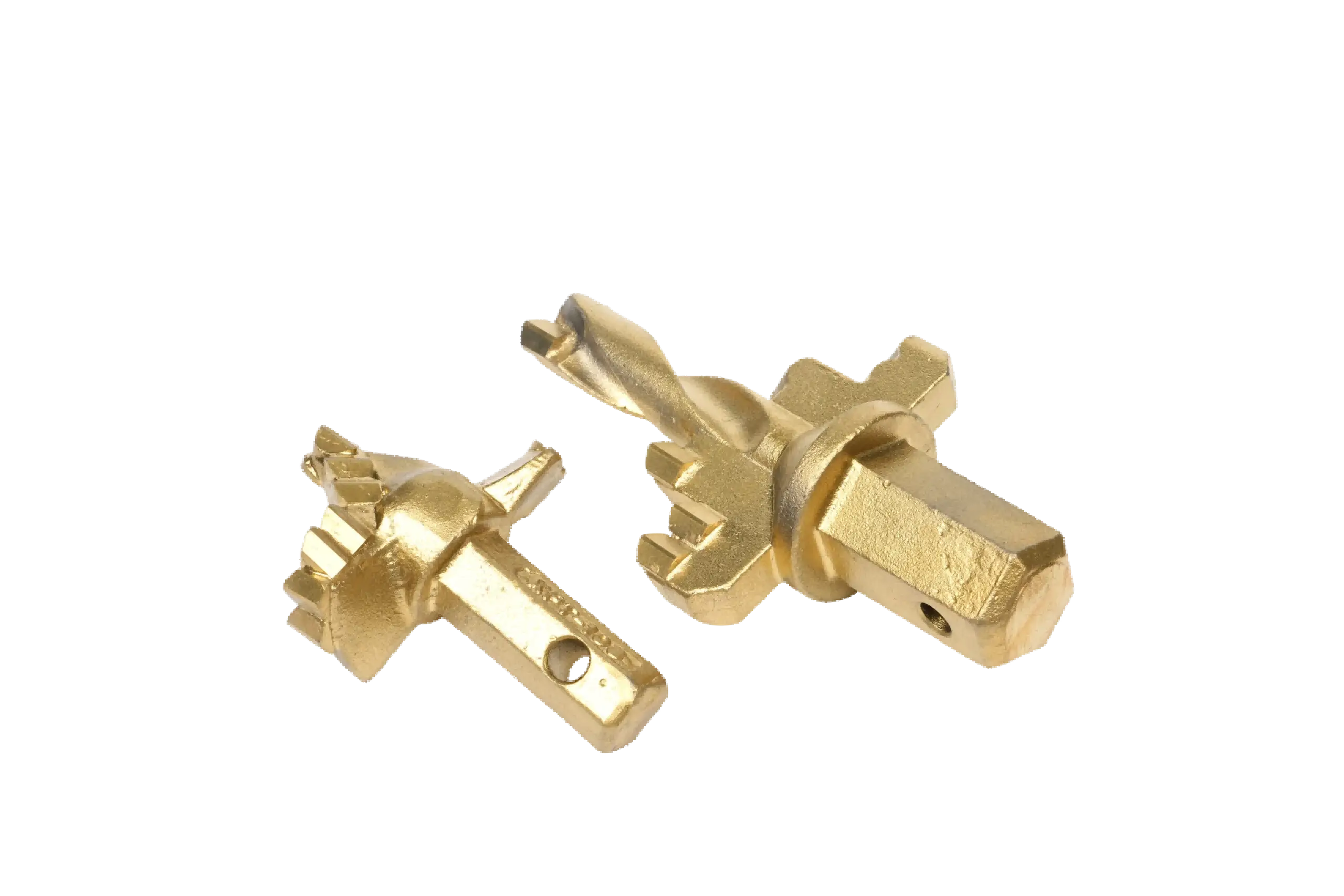

Developing New Casting Processes: Focusing on developing advanced casting processes such as automated high-density clay sand molding, high-efficiency self-hardening sand casting, precision core assembly molding, shell casting, centrifugal casting, metal mold casting, iron mold sand coating, lost foam/V-type/full mold casting, as well as specialty casting processes such as light alloy high-pressure/extrusion/differential pressure/low-pressure/semi-solid/regulated pressure casting, and silica sol investment casting, to meet the quality and performance requirements of castings across various industries.

Developing Advanced Casting Equipment: Developing and applying intelligent, highly automated casting equipment, such as automated molding lines, high-precision melting equipment, and advanced core-making equipment, to improve production efficiency and product quality consistency.

4. Developing Specialty Casting Technologies

Researching and developing new specialty casting technologies, such as high-precision die casting, vacuum die casting, and high-temperature alloy casting, to meet the demand for high-performance castings in high-end sectors such as aerospace, defense, and military.

5. Integration and near-net-shape

Integrated die-casting and other process technologies will be more widely used, reducing the number of parts and assembly steps, improving production efficiency and product performance, and reducing costs. At the same time, near-net-shape technology will continue to develop, making the shape and size of castings closer to the final product, reducing subsequent processing allowances, and improving material utilization and production efficiency.