Dongjian Machinery Quality control and management is a crucial part of the machining process. High-performance machinery can not only improve product performance and reliability, but also reduce production costs and maintenance costs.

First, the impact of machining quality factors

Machining equipment

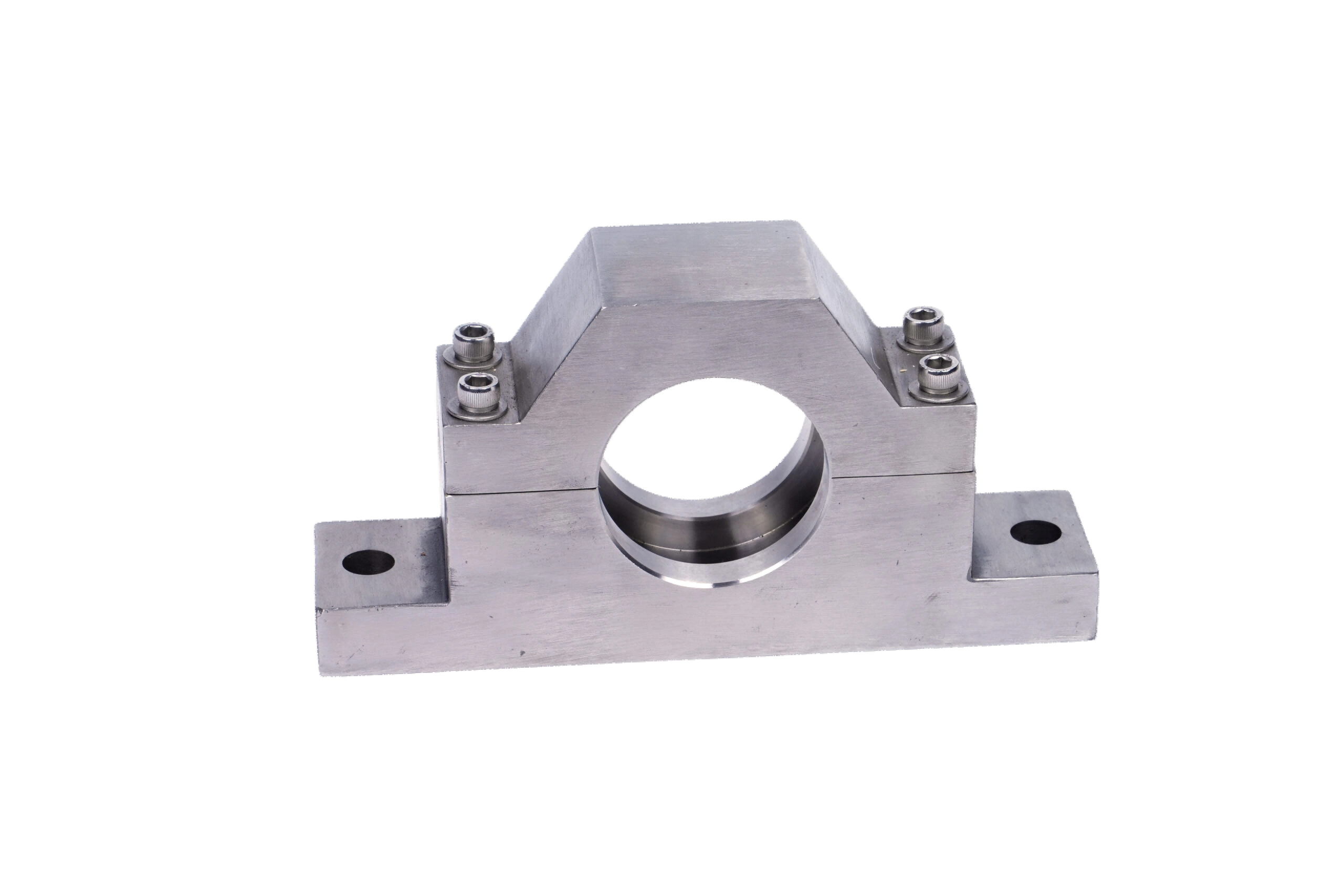

The precision and performance of machining equipment directly affects the processing quality of parts. High-precision machining equipment can ensure the dimensional accuracy and surface quality of parts.

For example, the precision and stability of CNC machining centers play a decisive role in the processing quality of parts. Maintenance and repair of equipment is also very important, regular maintenance and calibration can ensure that the equipment is always in good working condition.

Machining process

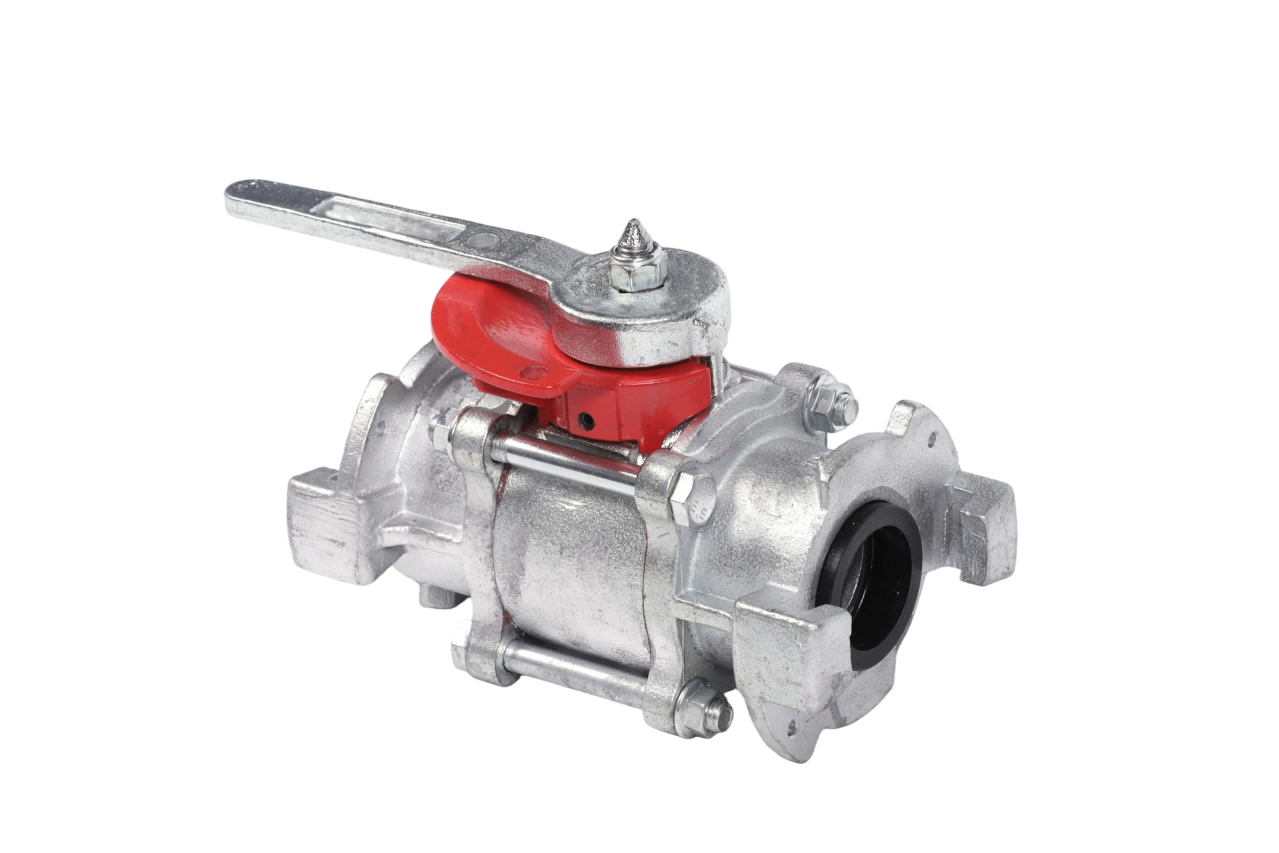

Reasonable machining process is the key to ensure the quality of parts. Different materials and shapes of parts require different machining processes.

For example, for materials with high hardness, it is necessary to choose appropriate tools and cutting parameters to avoid rapid tool wear and degradation of the surface quality of the part. Optimization of machining process can improve machining efficiency and quality and reduce production cost.

Operator

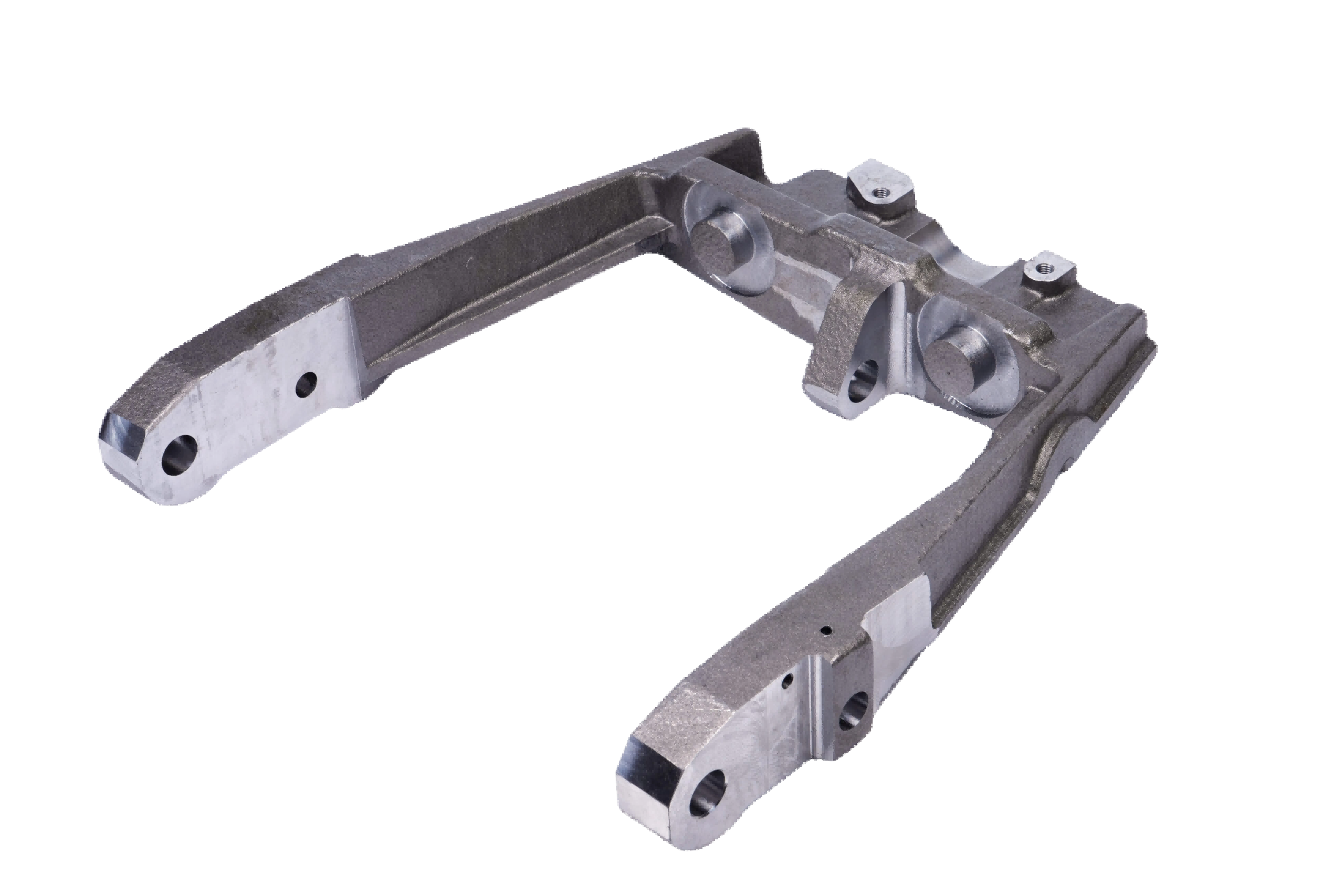

The operator's technical level and work attitude also have a great impact on the machining quality of parts. Skilled operators can correctly operate the machining equipment, rationally select the machining parameters, timely detection and resolution of problems in the machining process.

Second, quality control methods

First piece inspection

In mass production before the first piece of machined parts for a comprehensive inspection to ensure that it meets the design requirements. The first piece of inspection can be found in the process of processing problems, timely adjustment of processing parameters, to avoid the production of batch nonconforming products.

Process inspection

In the process of processing, regular inspection of parts to ensure the stability of processing quality. The process inspection can find abnormalities in the machining process in time, and take corresponding measures to adjust.

Final inspection

Comprehensive inspection of the finished parts to ensure that they meet the quality standards. Final inspection includes dimensional accuracy, surface quality, hardness and other aspects of the test.

In short, the quality control and management of machining is a systematic project, need to start from the processing equipment, processing technology, operators and other aspects, to take effective quality control methods and management systems, to ensure that the processing quality of parts.