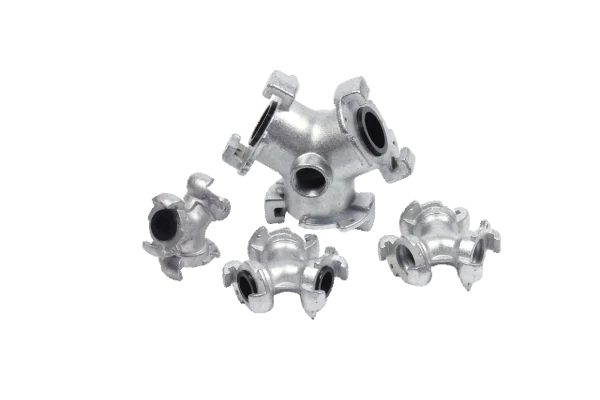

When your industrial operations demand uncompromising torque transmission, vibration dampening, and durability in the harshest environments, partnering with a trusted high-torque claw couplings factory is non-negotiable. Ningbo Dongpei Machinery Co., Ltd.—a leading high-torque claw couplings factory—engineers and manufactures premium claw couplings designed to excel in high-stress applications like mining, heavy construction, steel processing, and marine propulsion. Crafted from high-quality galvanized steel and premium elastomeric spiders, our claw couplings deliver exceptional high-torque performance, misalignment compensation, and maintenance-free operation, all while withstanding moisture, corrosion, and continuous shock loads. As a dedicated factory with precision manufacturing capabilities and engineering expertise, we don’t just supply claw couplings—we create custom-tailored power transmission solutions that keep your critical machinery running efficiently and safely, 24/7.

Why Choose a Specialized High-torque Claw Couplings Factory Like Ningbo Dongpei?

Not all manufacturers can deliver the precision, strength, and reliability required for high-torque claw couplings—generic couplings from non-specialized suppliers fail under the extreme stress of mining, heavy industry, and marine applications, leading to costly downtime, equipment damage, and safety risks. As a dedicated high-torque claw couplings factory, Ningbo Dongpei stands apart with our unwavering focus on engineering excellence, premium material selection, and custom manufacturing capabilities: we forge and machine coupling hubs from high-strength galvanized steel for corrosion resistance and structural integrity, mold our own elastomeric spiders from advanced polyurethane and Hytrel materials for superior torque handling and vibration dampening, and precision-balance every assembly for smooth operation at rated speeds. Unlike third-party resellers, our factory controls every step of the manufacturing process—from raw material inspection to final performance testing—ensuring every claw coupling meets or exceeds international quality standards. For businesses in mining, aggregate processing, and heavy industry, we are more than a factory: we are your technical partner, providing application support, custom bore/keyway designs, and reliable logistical support to keep your drivetrains running at peak performance.

Core Advantages of Ningbo Dongpei’s High-torque Claw Couplings (Engineered in Our Factory)

As a specialized high-torque claw couplings factory, we design every component of our couplings with the unique demands of harsh industrial environments in mind—our products deliver a perfect blend of power, durability, and practicality that sets them apart from generic alternatives:

- High-Strength Galvanized Steel Hubs for Unbeatable DurabilityOur coupling hubs are precision-machined from premium galvanized steel, a material chosen for its exceptional corrosion resistance, structural strength, and ability to withstand moisture, dust, and chemical exposure—common in mining, marine, and construction sites. The galvanized silver finish not only enhances aesthetic appeal but also creates a protective barrier against rust and degradation, ensuring long-term performance in the most demanding conditions without frequent replacement.

- Advanced Elastomeric Spiders for High-Torque & Vibration DampeningThe heart of our claw couplings is our factory-molded elastomeric spider (insert), available in high-grade polyurethane and Hytrel materials. These premium spiders deliver superior high-torque transmission while acting as a cushion to absorb shock loads and dampen vibration—protecting expensive connected equipment like gearboxes, motors, and bearings from premature wear and failure. Our spiders also offer excellent temperature resistance and chemical compatibility, making them ideal for diverse industrial applications.

- Precision Engineering for Misalignment Compensation & Smooth OperationEvery high-torque claw coupling from our factory is precision-balanced to ISO 1940 G6.3 standards as a complete assembly, ensuring smooth operation at maximum rated RPM without inducing excess vibration. The interlocking claw/jaw mechanism is engineered to accommodate minor parallel, angular, and axial shaft misalignment—an inevitable issue in real-world machinery installations—while maintaining a secure positive engagement for reliable power transfer, even under extreme load.

- Maintenance-Free, Lubrication-Free Design for Operational EfficiencyUnlike gear couplings and other power transmission components, our claw couplings feature a lubrication-free, maintenance-free design that eliminates costly and time-consuming maintenance tasks. There are no greasing points or moving parts to service, and wear on the elastomeric spider is easily visible for proactive replacement—minimizing unplanned downtime and reducing operational costs for your business. The simple two-hub-and-spider design also allows for quick installation and removal, speeding up equipment repairs and replacements.

- Custom Manufacturing Capabilities for Tailored SolutionsAs a full-service high-torque claw couplings factory, we offer complete custom manufacturing to meet your unique application needs. Our engineering team can design custom bore sizes, keyways, and hub dimensions to fit your specific motor and driven equipment shafts, as well as tailor spider materials (urethane, Hytrel, NBR) for your operating temperature range and fluid exposure conditions. Whether you need a coupling for a mining crusher, heavy-duty pump, or marine winch, we engineer a solution that fits perfectly—no one-size-fits-all limitations.

- Rigorous In-Factory Quality Testing & CertificationWe implement strict quality assurance protocols at every stage of manufacturing in our factory, including 100% dimensional inspection of critical features (bore size, keyways, claw geometry) using CMM and optical comparators, material certification for all steel and elastomer raw materials, and performance testing to validate torque ratings and burst speed capabilities. All our claw couplings are manufactured to ISO 9001 quality standards, and we provide detailed inspection reports and material certs with every shipment—ensuring consistent, reliable quality batch after batch.

Key Applications for Our Factory-Made High-torque Claw Couplings

Our high-torque claw couplings are engineered to be the critical power transmission link in industries where downtime is costly and performance is non-negotiable—leveraging our factory’s precision engineering and premium materials to excel in the most demanding applications:

- Mining & Aggregate Processing: Conveyors, crushers, ball mills, and screeners that start under load and experience continuous high torque and shock loads in dusty, moist underground and open-pit mine environments.

- Heavy-Duty Pumps & Compressors: Large centrifugal pumps, reciprocating compressors, and vacuum pumps in water treatment, oil & gas, and chemical plants—handling high torque while dampening vibration to protect pump components.

- Steel & Paper Mills: Heavy rollers, mixers, and extruders in high-heat, high-moisture environments—delivering reliable power transfer while accommodating shaft misalignment from thermal expansion.

- Marine & Offshore: Auxiliary drives, pump systems, winches, and propeller drives on ships and offshore platforms—resisting saltwater corrosion and handling the high torque of marine machinery.

- Construction & Heavy Machinery: Concrete mixers, excavators, and bulldozer drivetrains—withstanding shock loads and rough operating conditions while requiring minimal maintenance.

- Plastics & Food Processing: High-performance mixers and extruders—offering lubrication-free operation for clean environments and precise torque transmission for consistent production.

What to Look for in a Reliable High-torque Claw Couplings Factory

Selecting the right high-torque claw couplings factory is a strategic decision that impacts the reliability, safety, and efficiency of your industrial machinery—avoid generic suppliers and prioritize factories that meet these critical benchmarks (all of which Ningbo Dongpei fulfills):

- In-House Manufacturing & Engineering: A top factory controls every step of production, from forging/casting hubs to molding spiders, and has an in-house engineering team for application support and custom design.

- Premium Material Sourcing & Certification: The factory uses high-strength steel for hubs and advanced elastomers for spiders, with full material certification and traceability for all raw materials.

- Rigorous Quality Testing: The factory performs dimensional inspection, performance testing, and dynamic balancing in-house, with adherence to international quality standards like ISO 9001.

- Customization Capabilities: The factory offers custom bore sizes, keyways, and spider materials to fit your specific machinery and operating conditions.

- Application Expertise: The factory has deep knowledge of high-torque industries (mining, marine, steel) and can provide technical guidance on coupling sizing and selection.

- Reliable Lead Times & Spare Parts Support: The factory maintains inventory of standard couplings and offers fast lead times for custom orders, with regional support for spare spiders and hubs to minimize downtime.

FAQ: Your Questions About Our High-torque Claw Couplings Factory Answered

Q1: What materials do you use for the hubs and spiders in your high-torque claw couplings?

A: As a specialized high-torque claw couplings factory, we manufacture hubs from premium galvanized steel for superior corrosion resistance and structural strength—ideal for harsh mining, marine, and industrial environments. Our spiders are factory-molded from advanced elastomers including high-grade polyurethane, Hytrel, and NBR; polyurethane offers excellent torque handling and vibration dampening for general industrial use, Hytrel provides superior temperature and chemical resistance, and NBR is ideal for oil and fluid-exposed applications. Our team can guide you on the best material for your specific operating conditions.

Q2: Can you manufacture custom high-torque claw couplings for my specific shaft sizes and keyways?

A: Absolutely! Custom manufacturing is a core strength of our high-torque claw couplings factory—our engineering team can design and machine custom bore sizes, keyway dimensions, and hub lengths to perfectly fit your motor and driven equipment shafts (e.g., crushers, pumps, winches). We also offer custom spider materials and hardness ratings for your operating temperature range and fluid exposure. Simply share your shaft specs and application details, and we’ll create a tailored coupling solution for you.

Q3: Are your high-torque claw couplings tested for performance and quality in your factory?

A: Yes—we implement rigorous in-factory quality testing for every batch of claw couplings. This includes 100% dimensional inspection of critical features (bore size, keyways, claw geometry) using CMM and optical comparators, dynamic balancing to ISO 1940 G6.3 standards for smooth operation, torque testing to validate published torque and burst speed ratings, and material certification for all steel and elastomer raw materials. All our couplings are manufactured to ISO 9001 quality standards, and we provide detailed inspection reports and material certs with every shipment.

Q4: How do your claw couplings handle shaft misalignment, and what types of misalignment do they compensate for?

A: Our factory-engineered claw couplings are designed to accommodate minor parallel, angular, and axial shaft misalignment—the three most common types of misalignment in real-world machinery installations. The interlocking claw/jaw mechanism and flexible elastomeric spider work together to absorb misalignment without placing excess stress on connected equipment (motors, gearboxes, bearings), which prevents premature wear and failure. This misalignment compensation is critical for heavy industrial machinery, where thermal expansion, foundation settling, and normal wear can cause shaft misalignment over time.

Q5: What is the lead time for standard and custom high-torque claw couplings from your factory?

A: As a direct high-torque claw couplings factory, we offer fast lead times for both standard and custom couplings: standard sizes are available in our factory inventory with lead times of 3-5 business days for small orders, while custom couplings (custom bore sizes, keyways, or spider materials) have a lead time of 7-10 business days—far faster than most specialized manufacturers. We also maintain inventory of spare elastomeric spiders for all our coupling sizes, ensuring you can quickly replace worn spiders and minimize unplanned downtime for your operations.

Final Thoughts: Partner with the Leading High-torque Claw Couplings Factory – Ningbo Dongpei

In heavy industry, the claw coupling is the critical link that connects your power source to your driven equipment—its performance directly impacts the reliability, safety, and profitability of your operations. Ningbo Dongpei Machinery Co., Ltd. is more than just a high-torque claw couplings factory: we are your dedicated power transmission partner, with the precision manufacturing capabilities, engineering expertise, and premium material selection to create claw couplings that excel in the harshest mining, industrial, and marine environments.

Our galvanized steel claw couplings deliver unbeatable corrosion resistance, high-torque performance, and vibration dampening, while our maintenance-free, lubrication-free design reduces operational costs and downtime. As a full-service factory, we offer custom manufacturing to fit your unique machinery specs, rigorous in-house quality testing for consistent reliability, and responsive technical support to guide you on coupling selection and sizing.

Choose Ningbo Dongpei as your trusted high-torque claw couplings factory, and invest in power transmission components that are engineered for performance, built to last, and tailored to your needs. Contact our factory today to discuss your application requirements, request a custom quotation, or learn more about our premium high-torque claw couplings.