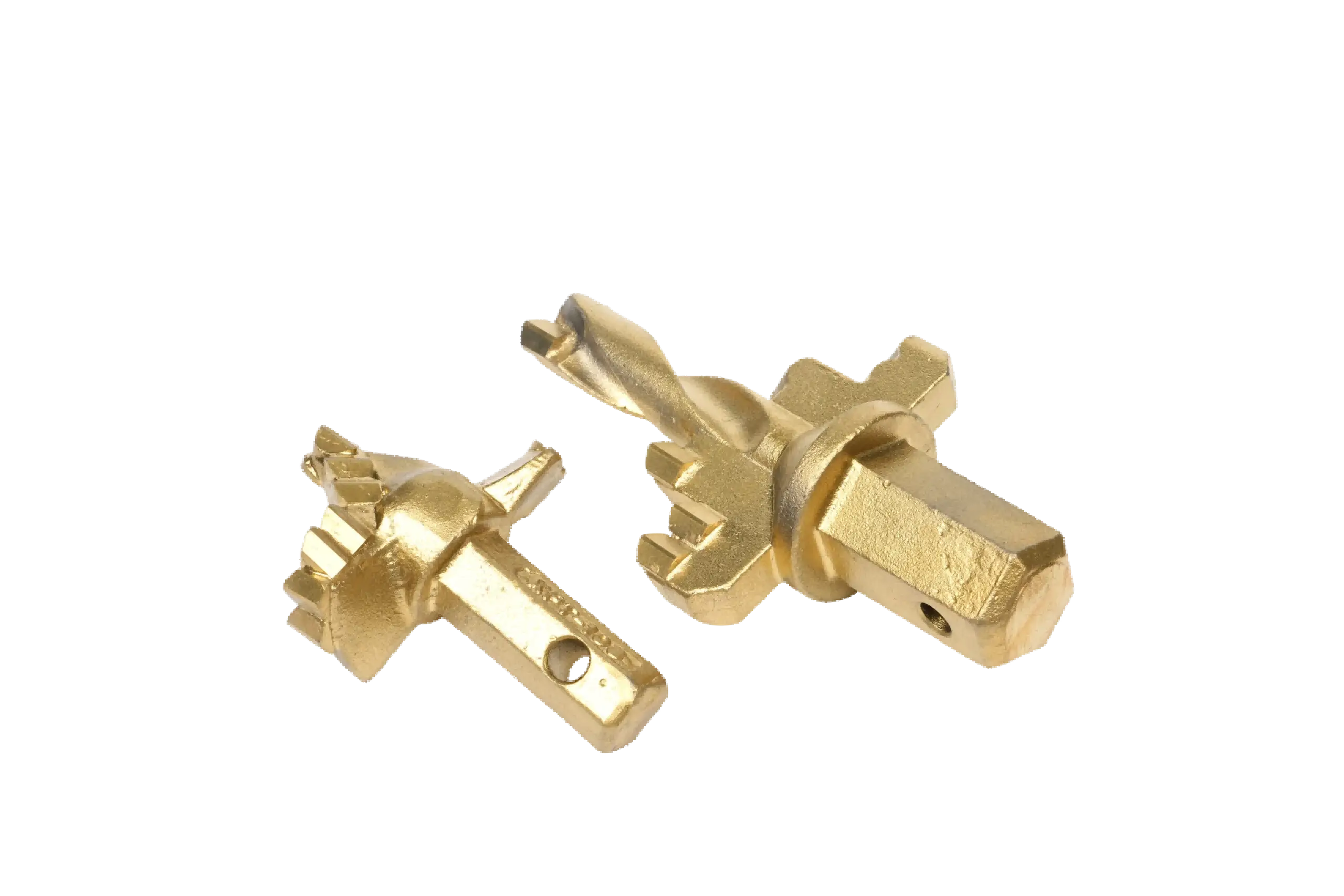

Dongpei is a professional greensand casting sand factory. Below is a detailed introduction to green sand casting:

Green sand casting is a casting process that uses green sand to create a mold. The “green” here does not refer to the color, but rather to the fact that metal is poured into uncured, “wet” sand, much like “greenwood” refers to wood with a high moisture content. The main components of green sand include sand, clay, silt, anthracite, and water, with sand being the primary component.

l Customized greensand casting sand process:

Preparing the sand mold: Prepared green sand is compacted around a pattern placed in a sand box to form a mold. The mold is typically divided into a cope (upper box) and a drag (lower box), with the dividing line between the two being called the parting line.

Removing the mold: After the mold has been compacted into the sand mold, it is removed, leaving a mold cavity for subsequent pouring of molten metal.

Pouring the metal: Molten metal enters the mold cavity through the sprue cup, sprue, runner, and ingate. To ensure the quality of the casting, risers are also provided in the mold to compensate for shrinkage of the molten metal during solidification.

Cooling and Solidification: The molten metal cools and solidifies within the mold cavity, forming the casting.

Removing the Casting: After the casting has cooled, the mold is broken and the casting is removed. Cleaning, polishing, and other subsequent processing steps are then carried out.

l Features:

Advantages: The production process is simple and easier to operate and master than other casting processes. The production cost is low, as green sand is inexpensive and the preparation process is relatively simple. It is also recyclable, reducing material costs. The production efficiency is high, and mechanized and automated molding equipment can be used to achieve mass production and improve production efficiency.

Disadvantages: The surface quality of the casting is poor, and defects such as pinholes, air holes, and sand adhesion are prone to occur, resulting in high surface roughness. Dimensional accuracy is low, with dimensional tolerances typically in the CT11-CT12 range, making it suitable only for castings with low dimensional accuracy requirements. The internal quality of the casting is difficult to control. Due to the limited permeability and yield properties of green sand, defects such as shrinkage cavities and porosity are prone to occur within the casting.

l Applications:

Green sand casting is widely used in various industries, including automotive, machinery, and construction. In the automotive industry, it can be used to produce key components such as engine cylinder blocks and crankcases; in the machinery industry, it can be used to manufacture precision parts such as various gears and bearings; and in the construction industry, it can be used to produce various prefabricated components such as bridges and tunnels.

Contact Dongpei a greensand casting sand manufacturer in China, and let us use our professional sand mold technology to build a solid foundation for your products!