In the modern manufacturing industry, the quality of machining directly affects the performance of the product and the competitiveness of the market. As Ningbo Dongju Machinery Manufacturing Co., Ltd, we know that quality is the lifeline of an enterprise. Since the establishment of the company, we have always adhered to the principle of “quality first”, and have carried out quality control in every link of production to ensure that every product meets the high standard requirements of customers.

Establishment of perfect quality management system

Quality management is the basis for ensuring the precision and stability of machined products. Dongjian Machinery always pays attention to the construction and optimization of quality management system. We rely on international advanced quality management standards, such as ISO9001 quality management system, to build a set of perfect quality control process. Each batch of raw materials, the use status of each piece of equipment, and the operation process of each production line are all executed in strict accordance with the standards to ensure that the product quality can be strictly controlled from the source to the end.

Strict inspection and control of raw materials

High-quality machining products cannot be separated from high-quality raw materials. In order to ensure the quality of our products, Dongjian Machinery is very strict in the selection of raw materials, and all raw materials are strictly inspected and certified. We have established long-term and stable relationships with many well-known suppliers at home and abroad to ensure the reliability and high standard of raw materials. After each batch of raw materials arrives at the factory, several quality tests will be conducted, such as hardness, dimensional accuracy, material composition, etc., to ensure that they meet the processing requirements.

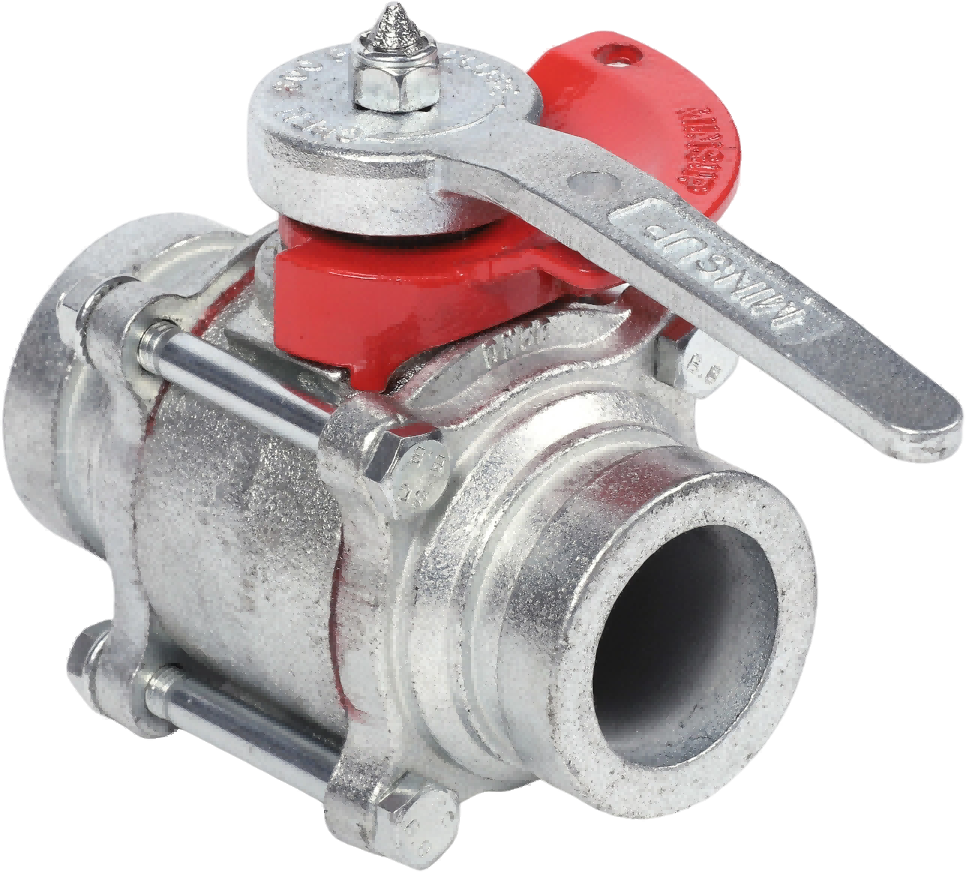

High-precision production equipment

In machining, the precision of the equipment directly determines the quality of the processed products. Dongjian Machinery has introduced many advanced CNC machine tools, laser cutting machines, precision grinding machines and other high-precision equipments to ensure that the products meet the requirements of precision in the machining process. All equipment is regularly maintained and calibrated to ensure that it is in the best working condition. By constantly optimizing the performance of production equipment and adjusting the process flow, we are able to effectively reduce processing errors and improve production efficiency.

Whole Process Quality Control

Dongjian Machinery implements whole-process quality control, from design, production to testing, every step of the process is strictly controlled. During the production process, we adopt an advanced automated monitoring system to track the operating status of each machine in real time, so that potential quality problems can be detected and solved in a timely manner. In addition, our technical team regularly checks the process and optimizes the production process to further improve the stability and consistency of our products.

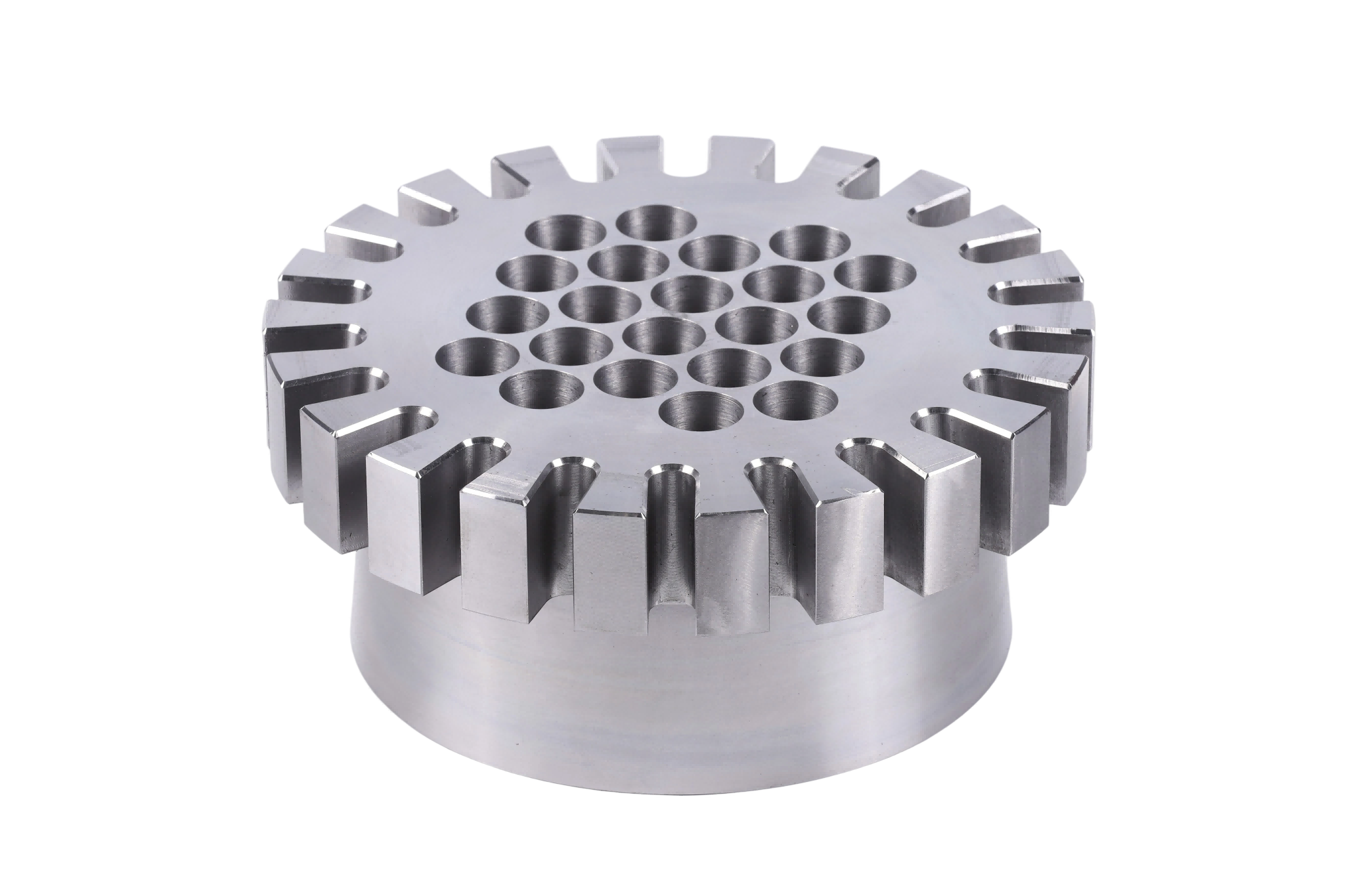

Precise Quality Inspection

Dongjian Machinery has an experienced quality inspection team equipped with advanced testing equipment, including CMMs, projectors, hardness testers and other high-precision instruments. After the production is completed, each product needs to go through strict quality inspection to ensure that it meets the design requirements and customers' standards. We will check the appearance, size, precision, durability and many other aspects of the product to ensure that every delivered product can be perfect.

Continuous Improvement and Innovation

Quality management is not only a process, but also a dynamic process of continuous improvement. Dongjian Machinery constantly promotes technological innovation and focuses on the continuous optimization of research and development and production processes. In quality management, we encourage our employees to propose improvements and raise the quality awareness of all staff through training and teamwork. We also conduct regular quality reviews to analyze and summarize problems in production, formulate improvement measures, and push the company forward in quality management.

Quality is the core competitiveness of an enterprise, and this is especially true in the machining industry. As an enterprise dedicated to high-quality machinery manufacturing, Dongjian Machinery always takes quality control and management as the fundamental of enterprise development. By constantly optimizing the quality management system and strictly controlling each production link, we are not only able to guarantee the quality of our products, but also improve customer satisfaction and win the trust and recognition of the market. Looking to the future, Dongjian Machinery will continue to uphold the principle of “quality first”, promote technological innovation and quality improvement, and provide customers with more high-quality, reliable machinery products.