Core Principle:

l A mold with the same shape as the casting is made using a fusible material (such as wax), and then assembled into a mold assembly.

l Multiple layers of refractory coating are applied to the surface of the mold assembly, and sand is sprinkled on top to form a high-strength shell.

l The mold material is heated to melt it away, leaving a hollow cavity in the shell. Molten metal is poured in, and after cooling, the casting is obtained.

Key Steps:

1. Mold Material Preparation: Wax, resin, etc., are mixed according to the formula to ensure fluidity and formability.

2. Mold Making and Assembly: Individual wax molds are pressed using a mold, and multiple wax molds are then attached to the gating and riser rods.

3. Shell Manufacturing: Refractory slurry (such as silica sol + corundum powder) is applied multiple times, and sand is sprinkled on top. After drying and hardening, the shell is formed.

4. Dewaxing and Shell Firing: The mold material is heated to melt and flow out, and then the shell is fired at high temperature to improve strength and permeability.

5. Pouring and Cleaning: Molten metal is poured into the shell, cooled, and then the shell is broken. The gating and riser are removed, and the shell is polished.

Key Advantages:

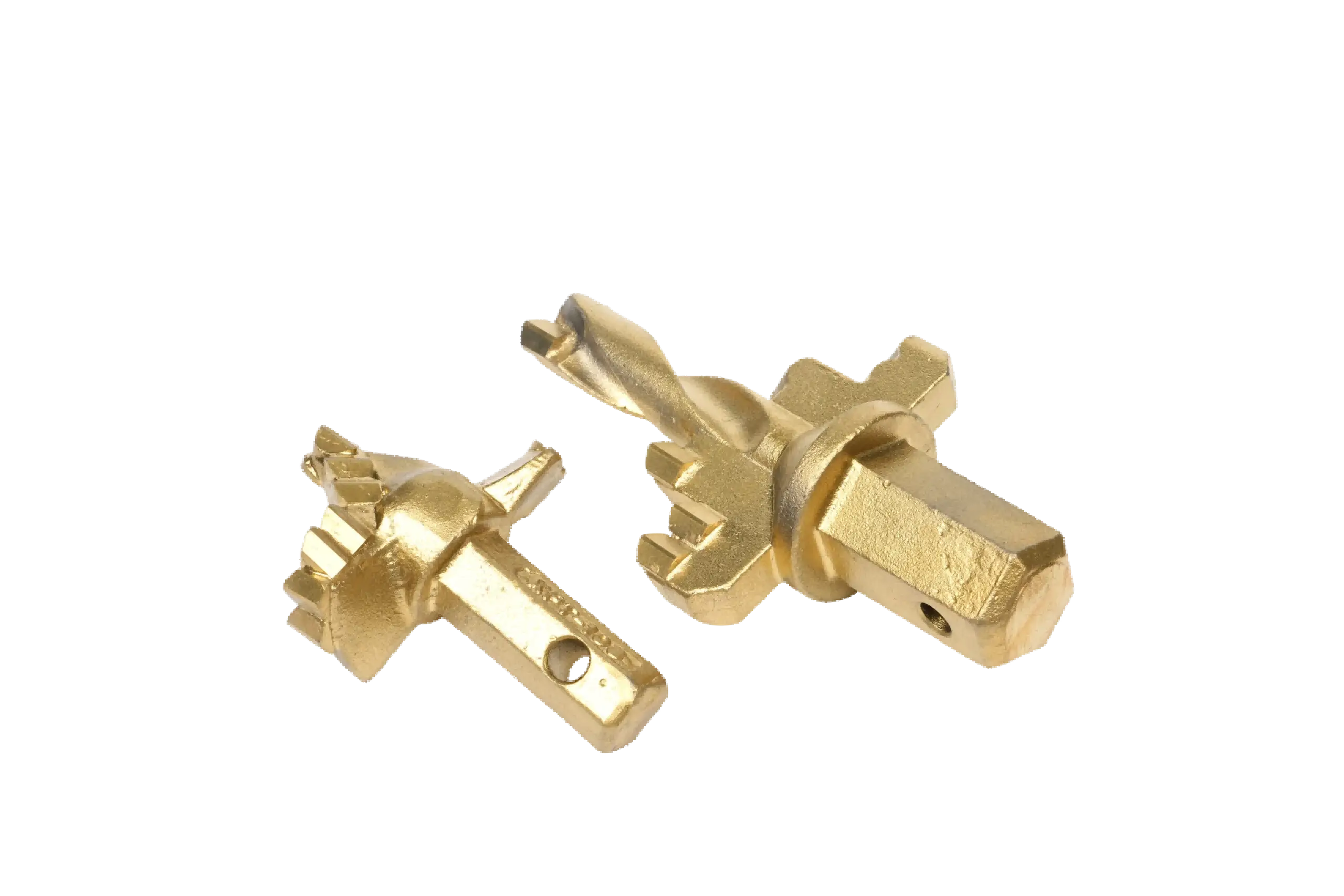

l High casting precision (dimensional tolerances up to IT5-IT7), low surface roughness, reducing subsequent machining.

l Capable of casting complex shapes (such as hollowed-out, thin-walled, and irregularly shaped parts) and difficult-to-machine alloys (such as high-temperature alloys and stainless steel).

l No need for large molds, suitable for small-batch, multi-variety production.

Invest Casting Process Manufacturers China

Dongpei Invest Casting Process Factory specializes in investment casting (lost-wax casting) technology, deeply integrating traditional processes with modern digital technology to provide high-standard casting services for aerospace, automotive, medical, and high-end equipment industries.

Investment casting eliminates the need for molds, accurately replicating complex internal cavities, curved surfaces, and other intricate structures. Investing achieves dimensional accuracy of 5-7 levels and a low surface roughness of Ra6.3μm. This process is suitable for casting various materials such as stainless steel and heat-resistant alloys, with a material utilization rate exceeding 80%, significantly reducing subsequent machining allowances. By combining digital management and silica sol shell-making technology, Dongpei effectively avoids defects such as sand holes and porosity, balancing the efficiency requirements of small-batch customization and mass production.

From technology research and development to finished product delivery, Dongpei invest casting process Suppliers leverages its process advantages to solidify its quality foundation, becoming a trusted investment casting partner in the industry.