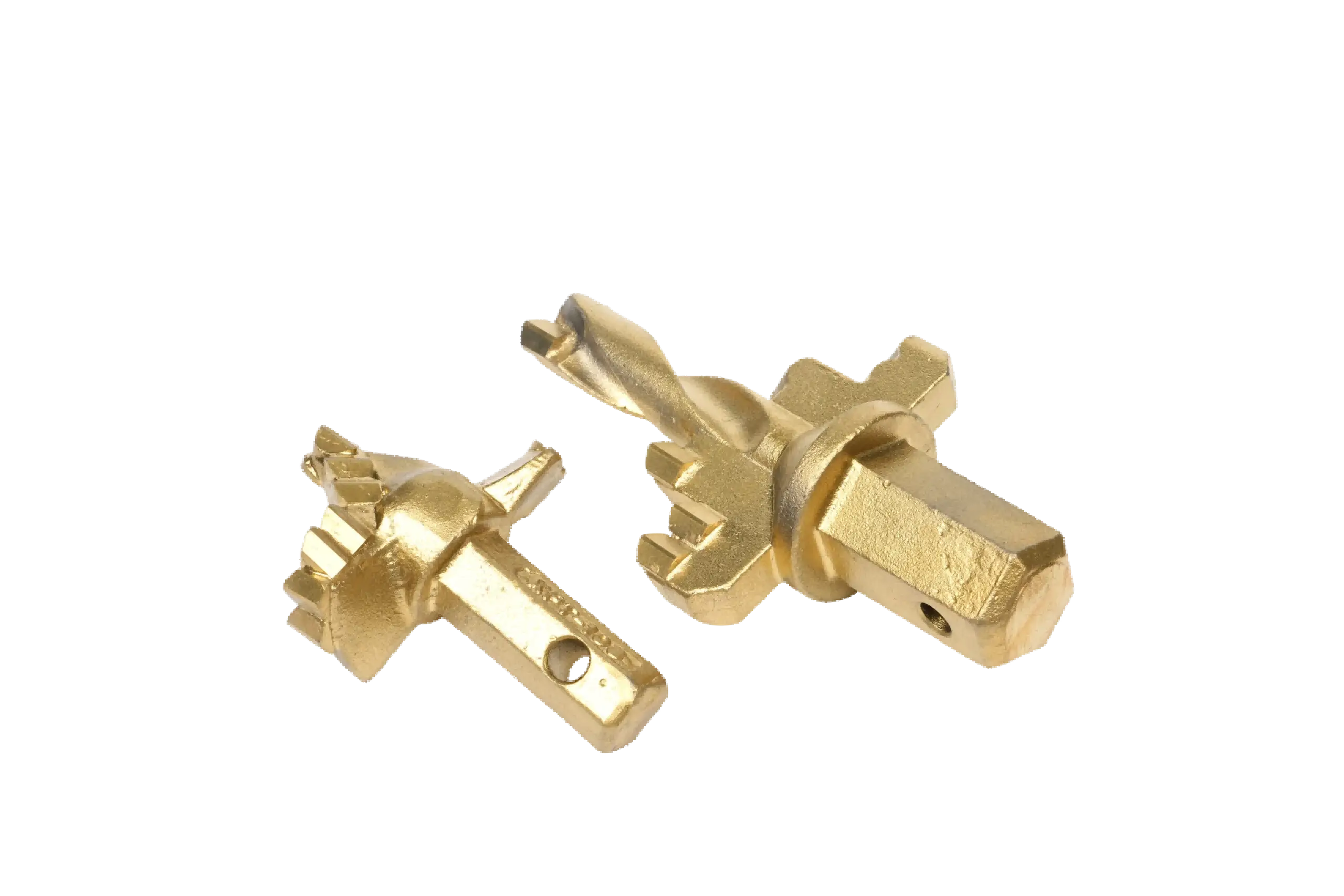

A ball bearing seat is a mechanical component used to support and secure ball bearings, playing a crucial role in mechanical equipment. Here is a detailed introduction:

l Function: Its main function is to secure the ball bearing, ensuring stable operation under high-speed, high-load, and high-precision conditions, reducing bearing vibration and displacement, and guaranteeing normal machine operation.

l Structure: It typically includes components such as a base, base plate, adjusting screws, and fixing screws. The base is the foundation for securing the ball bearing; the base plate supports the lower part of the ball bearing; the adjusting screws are used to adjust the bearing’s level and perpendicularity; and the fixing screws are used to secure the adjusted position.

l Types:

By structural form: It can be divided into open bearing housings, closed bearing housings, and split bearing housings. Open bearing housings have a simple structure and low cost; closed bearing housings have good sealing performance; split bearing housings are easy to install and disassemble.

By application: It can be divided into fixed-end bearing housings and support-end bearing housings. Fixed-end bearing housings are used to secure lead screws and usually use angular contact bearings; support-end bearing housings generally use deep groove ball bearings.

l Materials: Commonly used materials include cast iron, steel, and aluminum alloys. Cast iron offers good corrosion resistance and wear resistance at a lower cost; steel boasts high strength and rigidity, making it suitable for heavy-duty and high-load machinery; aluminum alloys are lightweight, have excellent heat dissipation, and are often used in equipment where weight is a critical factor.

l Application Areas: Widely used in various mechanical equipment requiring high-load transmission and precision positioning, such as machining centers, CNC machine tools, and injection molding machines. It is also used in aerospace, automotive manufacturing, semiconductor manufacturing, and other industries with extremely high requirements for equipment precision and stability.

Dongpei Company specializes in the mechanical parts industry and is your trusted professional ball bearing seat manufacturers. We focus on the design and production of various ball bearing housings, split bearing housings, flange bearing housings, and other products, committed to providing high-performance, long-life bearing housing products for various industries.

We understand that standard parts cannot meet all application scenarios. Therefore, we offer flexible, non-standard customization services, tailoring the most suitable bearing housing solution to your specific needs based on your equipment space, load requirements, speed, and operating environment (such as high temperature, humidity, and high load). From material selection (such as cast iron, cast steel, and stainless steel) to precision machining, we strictly control every step to ensure high precision and superior durability of our products.

If you are looking for reliable, reasonably priced custom bearing housings, Dongpei Company is your best choice. Welcome to contact us for further discussion; let us solve your core support problems!