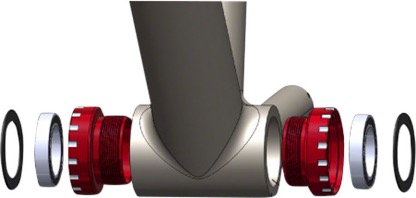

An external bottom bracket is a modern bicycle bottom bracket system where the bearings and bearing housings are located outside the bottom bracket (the tubular part at the bottom of the frame where the cranks are mounted) and secured to the frame by a large locking ring.

Simply put, it’s like a “big cap” that screws in from both sides of the bottom bracket, and the bearings are installed inside this “cap.”

Key Features:

1. External Bearings: This is the most fundamental difference between it and the old-style square-hole bottom bracket. The old-style bottom bracket bearings were installed inside the bottom bracket.

2. Larger Axle Diameter: To accommodate this design, the crank axle is also thicker (typically 24mm), significantly increasing rigidity.

3. Standardized Threaded Connection: The most common standard is British Standard Thread (BSA), also known as a “threaded bottom bracket.” The screw-in direction is “left-hand clockwise, right-hand counter-clockwise” (the drive side is counter-clockwise, the non-drive side is clockwise).

4. Two-piece construction: Typically consists of three parts:

l A bearing unit on the drive side (right side)

l A bearing unit on the non-drive side (left side)

l Two large locking rings (for securing and adjusting preload)

Advantages:

l Extremely high rigidity: Due to the wider bearing spacing and thicker axle, deformation is less during heavy pedaling, resulting in more direct and efficient power transfer. This is its most prized advantage.

l Lightweight: It can be made lighter than older one-piece bottom brackets.

l Superior performance: Provides better support for high-intensity and racing-level riding.

l Relatively easy maintenance and replacement: The entire bearing unit can be easily removed from the frame for maintenance or replacement using specialized tools.

Disadvantages:

l Preload adjustment: Proper bearing preload adjustment is required to prevent premature bearing wear or play. Improper adjustment may cause squeaking.

l Potential squeaking issues: If the locking rings are not tightened to the correct torque, or if dirt or sand gets into the mating surfaces, an annoying “squeaking” sound may develop after prolonged use.

l High precision is required for the bottom bracket machining of the frame: the mounting surfaces of the two bearing housings must be parallel and accurately spaced; otherwise, bearing life and smooth rotation will be affected.

l It is being replaced by more modern standards: Although it was once a symbol of high performance, it is now gradually being replaced by standards such as press-fit and the more advanced threaded T47.

Common Standards and Compatibility An external bottom bracket is a system concept, but to accommodate different brands of cranks, several standards have emerged. You may hear the following names, all of which fall under the category of external bottom brackets:

l Shimano Hollowtech II: This is the most common and widespread external bottom bracket system. The shaft diameter is 24mm.

l SRAM GXP: The shaft diameter is also 24mm, but the non-drive side is 22mm. It is not fully compatible with Shimano and requires a dedicated GXP bottom bracket.

l Campagnolo Ultra-Torque: Campagnolo’s exclusive standard, with a structure different from the other two.

External bottom brackets represent a significant technological advancement in bicycle development, achieving an excellent balance between rigidity, lightweight design, and performance. Despite minor drawbacks such as preload adjustment and potential squeaking, they remain one of the most reliable and mainstream bottom bracket standards for road and mountain bikes (especially threaded versions). When you see the crankshaft axle passing through a large metal ring, it’s essentially an external bottom bracket.

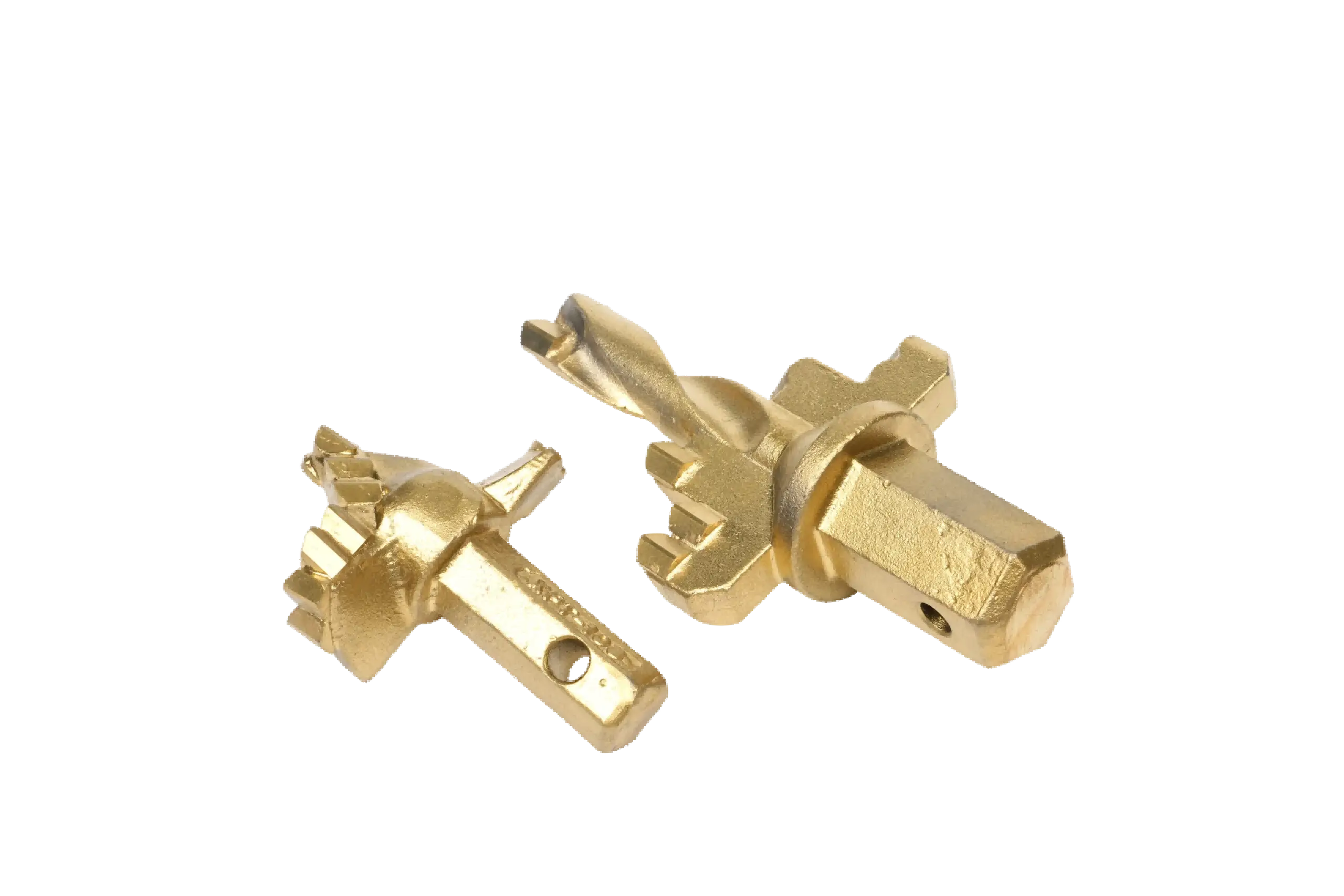

Dongpei Company: External Bottom Bracket Manufacturers China

In the world of bicycles, where ultimate performance and personalization are paramount, a superior bottom bracket is the core hub of power transmission. Dongpei understands this well, focusing on providing professional-grade customized external bottom brackets for global bicycle brands, frame manufacturers, and high-end riders, leveraging its exquisite craftsmanship and forward-thinking design.

From raw material warehousing to finished product delivery, every process is under our rigorous quality control. We employ high-precision CNC machining to ensure that the dimensional tolerances of every component are within the micrometer range.

Dongpei firmly believes that superior components are the foundation of an exceptional ride. If you are looking for a professional external bottom bracket factory, please contact us today for customized external bottom brackets.

Visit the Dongpei website or call our service hotline for free one-on-one technical consultation from our engineers.