1. The “Optimal Solution” for Small and Medium-Batch Costs: Eliminating the Dilemma of “Expensive Molds” and “Poor Precision”

Although sand casting offers low mold costs, its poor precision leads to skyrocketing post-processing costs (for example, a certain automotive part requires three additional milling steps after sand casting, increasing costs by 40%). High-pressure die casting offers high precision, but the million-dollar mold costs make small and medium-sized orders “unprofitable.”

Dongpei gravity die casting manufacturers achieve a 25%-35% reduction in overall costs compared to sand casting by combining low-cost metal molds with a long-life design.

2. Achieving Both Precision and Strength: Suitable for High-Demand Industrial Applications

Sand casting suffers from poor mold yield, which can easily lead to shrinkage cavities and cracks, resulting in tensile strengths often below 200 MPa. Low-pressure casting, while meeting strength standards, struggles to achieve precision exceeding CT8.

Dongpei achieved a dual breakthrough through mold preheating (200-300°C) and Huazhu CAE simulation optimization.

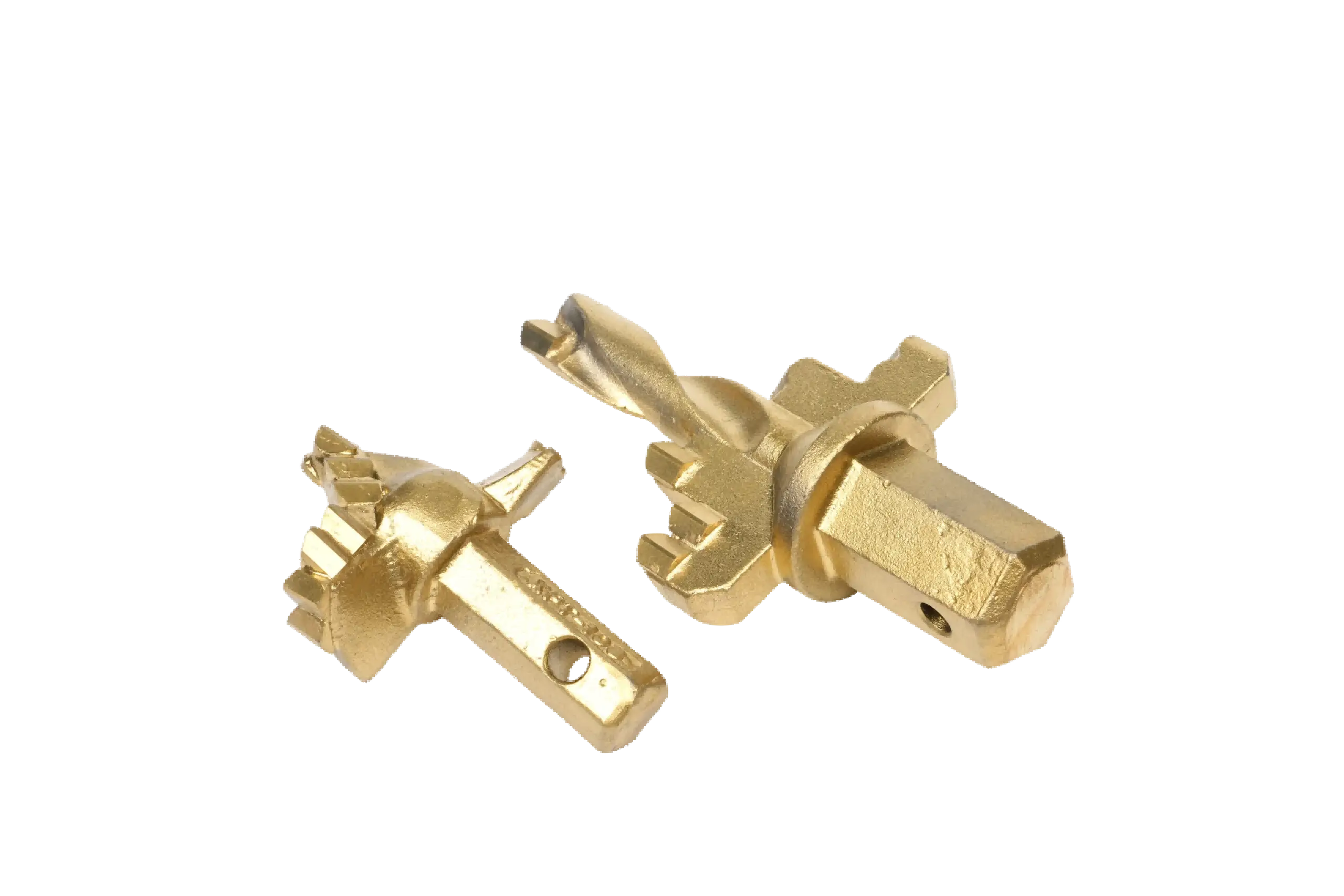

3. Process Flexibility: “No Shortcomings”: Compatible with Multiple Materials and Complex Structures

High-pressure die casting, limited by its “high pressure and high speed” characteristics, is only suitable for thin-walled aluminum alloy parts (wall thickness ≤ 3mm) and cannot produce high-density materials such as stainless steel. Sand casting, while compatible with a wide range of materials, struggles with forming complex structures (e.g., multi-cavity valve bodies are prone to under casting).

Dongpei gravity die casting factory achieves “full-scenario coverage” through multi-slide molds and customized gating systems:

Material: Aluminum, magnesium, zinc, and stainless steel parts can be produced.

Structure: Supports special-shaped parts weighing 0.5-150kg and with wall thicknesses of 3-50mm, such as robot joint housings (containing three internal cavities and two curved surfaces). The first-pass yield rate reaches 99.7%, a 17% improvement over sand casting (85%).

4. Energy Consumption and Delivery: “Dual Efficiency”: Balancing Environmental Protection with Stable Production Capacity

High-pressure die-casting requires 2000-3000 bar high-pressure equipment, consuming 800 kWh per ton of casting. Sand casting, while less energy-intensive (500 kWh per ton), is difficult to recycle and poses significant environmental risks.

Dongpei Gravity Die Casting achieves green production through a low-energy pouring process and the use of recycled aluminum:

Energy Consumption: Energy consumption per ton of casting is only 560 kWh, a 30% reduction compared to high-pressure die-casting. Combined with 30% recycled aluminum raw material, carbon emissions per ton are 25% lower than sand casting.

Dongpei Technology: Maximizing the Advantages of Gravity Die Casting

Full-Process Quality Control: From raw material spectral analysis (to ensure material purity) to finished product leak testing, ISO 9001/IATF 16949 certification ensures a strictly controlled defect rate below 0.3%, far exceeding the industry average of 1.5%;

Customized Solutions: Optimize processes to meet the needs of different industries;

Global Compliance: Products comply with standards such as ROHS, REACH, and medical-grade ISO 13485, making them suitable for European and American automotive and medical supply chains, serving over 200 global customers.

Customized Gravity Die Casting: When is Gravity Die Casting preferred?

If you need small to medium-sized batches of 1,000 to 50,000 pieces per year, with precision requirements of CT8 or higher and manageable costs; if your parts are made of aluminum-magnesium alloy or stainless steel, or require integrated molding of complex cavities or curved surfaces; if you require fast delivery (mass production within 15 days) while balancing energy efficiency and environmental protection.

With over 20 years of experience in gravity die casting, Dongpei gravity die casting factory, can provide you with free process selection and sample testing. Click here to inquire for a personalized quote.