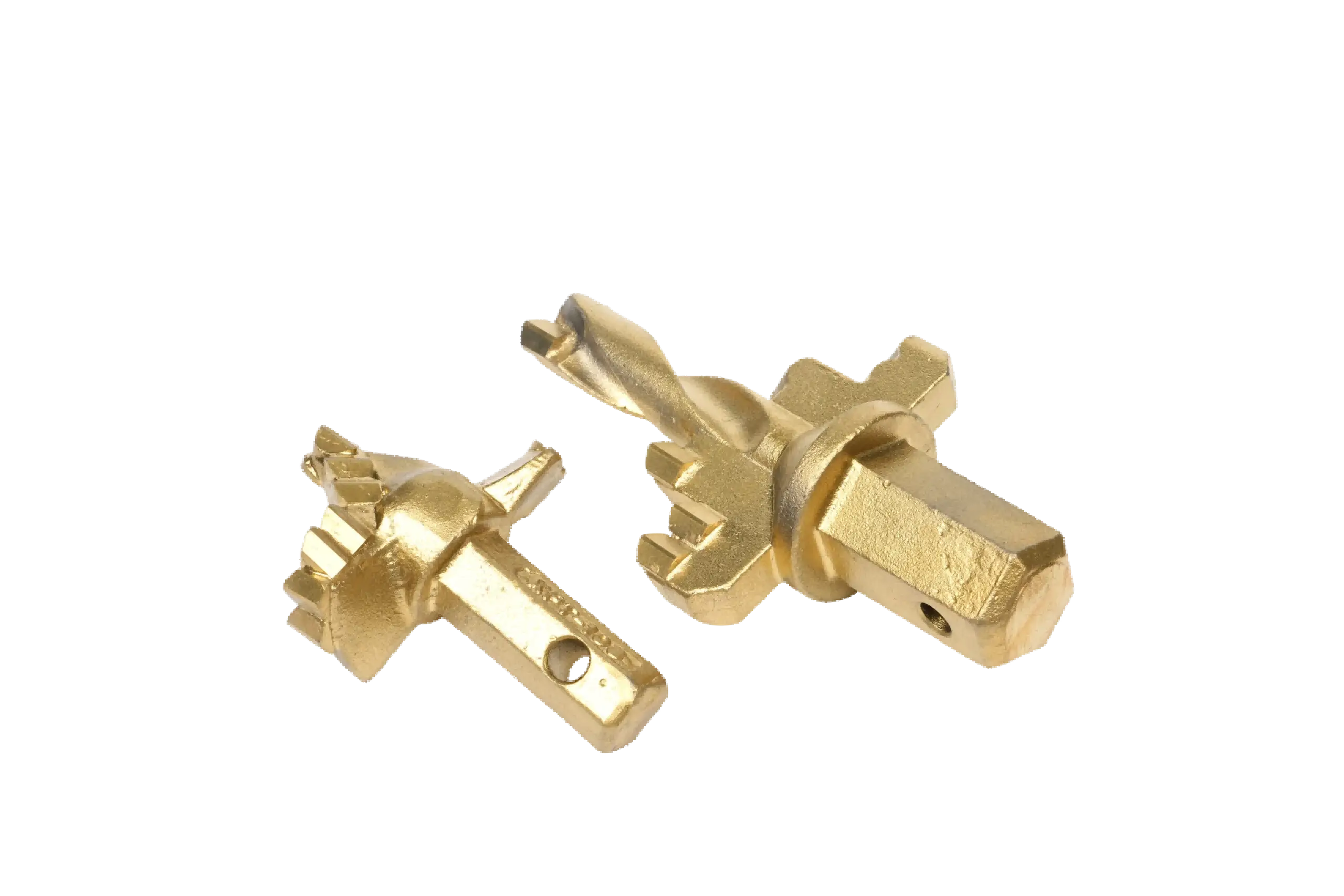

Dongpei, with deep expertise in transmission components, can customize flange shaft coupling on demand! Whether adapting to general equipment like pumps, fans, and machine tools, or addressing specialized applications like metallurgy and wind power, we can customize flange dimensions, materials, and structures based on torque, speed, and media requirements, ensuring both rigidity and stability while providing flexible compensation. Dongpei flange shaft coupling Factory with strict quality control and efficient delivery, we provide customized solutions for your transmission system, ensuring stable operation!

Flange shaft coupling is a rigid or flexible transmission device that connects two drive shafts using flanges, bolts, and other components. Its core function is to transmit torque, compensate for shaft misalignment, and, in some applications, provide cushioning, vibration reduction, or overload protection. Their stable structure, high torque transmission, and easy installation and maintenance have led to their widespread use in industrial transmission systems. The following is an analysis of specific application areas and scenarios:

I. General Machinery Manufacturing

General machinery represents the most fundamental application of flange couplings, encompassing a wide range of equipment requiring shaft-to-shaft transmission. Core requirements include stable torque transmission and medium load capability. Common applications include:

l Pumps, such as centrifugal pumps, screw pumps, and diaphragm pumps, connect motors to pump shafts. For example, corrosion-resistant centrifugal pumps in the chemical industry use stainless steel flange couplings to transmit motor power to the pump impeller, while also compensating for radial shaft misalignment caused by installation errors and preventing premature wear of pump seals.

l Fans and Compressors, such as centrifugal fans, Roots blowers, and air compressors, connect motors to the fan/compressor rotor shaft. For example, induced draft fans in power plants require high-torque flange couplings (often rigid or semi-flexible) to transmit high power while accommodating minor shaft misalignment caused by temperature fluctuations during fan operation.

l Machine tools: Spindle drive systems for lathes, milling machines, and grinders. Some heavy-duty machine tools utilize flange couplings to connect the motor and spindle housing to ensure stable torque transmission during cutting and avoid machining precision errors caused by transmission backlash.

II. Heavy Industrial and Engineering Machinery

Under heavy loads and harsh operating conditions, flange couplings must meet the requirements of high torque transmission, shock resistance, and wear resistance. Typical applications include:

l Metallurgical equipment: Such as rolling mills, continuous casting machines, and crushers. For example, hot rolling mills require a “rigid flange coupling + universal joint” combination to connect the main motor and roll shafts, transmitting thousands of Newton-meters of torque while compensating for axial displacement caused by thermal expansion and contraction, ensuring uniform thickness during steel plate rolling.

l Mining machinery: Such as mining crushers, ball mills, and belt conveyors. For example, the ball mill’s transmission system uses a heavy-duty cast steel flange coupling to connect the motor and the gearbox output shaft. This withstands the impact loads of grinding materials and prevents shaft fracture due to transient overload.

l Engineering machinery: Hydraulic pump transmissions in excavators, loaders, and cranes. Some large excavators use flexible flange couplings (containing rubber or elastic elements) between the engine and hydraulic pump. This not only transmits power but also cushions the impact during engine startup and protects the hydraulic pump’s internal precision components.

III. Energy and Power Systems

Energy systems require extremely high transmission reliability. Flange couplings must meet requirements for long life, low maintenance, and adaptability to extreme operating conditions. Key applications include:

l Power Industry:

Thermal Power Generation Units: Connecting the turbine and generator rotors typically uses a rigid flange coupling (such as a solid forging flange coupling). Because the turbine and generator require extremely high coaxiality, the rigid structure ensures zero transmission backlash and prevents excessive vibration during high-speed rotation (typically 3000 rpm).

Hydropower generators: Semi-flexible flange couplings (e.g., structures with elastic gaskets) are often used to connect turbines and generators. This compensates for minor angular misalignment of the shaft caused by water impact and reduces vibration transmission to the generator.

l New Energy Sector:

Wind turbines: Used to connect the gearbox and generator, some models utilize flexible flange couplings (containing polyurethane or metal elastic elements) to accommodate radial misalignment of the shaft caused by varying wind speeds during operation, while also buffering the gearbox’s impact loads and extending the generator’s life.

Photovoltaic pump systems: Lightweight aluminum alloy flange couplings are commonly used to connect the motor and pump shaft of small photovoltaic pumps, balancing weight and torque transmission requirements to accommodate the intermittent starting conditions of photovoltaic power supply.

IV. Transportation

Transportation equipment’s transmission systems must withstand the vibration, shock, and space constraints of mobile operating conditions. Flange couplings are primarily designed for compactness, vibration resistance, and fatigue resistance.

l Railway transportation: For example, in subway and light rail traction systems, compact flange couplings (such as diaphragm-type flexible flange couplings) are used between the traction motor and gearbox on some models. These couplings transmit traction torque while compensating for shaft misalignment caused by track irregularities and preventing gear meshing errors.

l Ship and Offshore Engineering:

Ship propulsion systems connect the main engine (diesel engine or gas turbine) to the propeller shaft. Heavy-duty marine flange couplings (such as cast steel integral flanges) are used. These couplings withstand seawater corrosion and high torque. The flange end faces provide positioning, ensuring shaft alignment and reducing propeller vibration.

Offshore platform equipment: For example, drilling pumps and oil transfer pumps on platforms utilize corrosion-resistant flange couplings (such as stainless steel or coated) to connect the motor and pump shaft. These couplings withstand high salt spray environments and prevent coupling rust and failure.