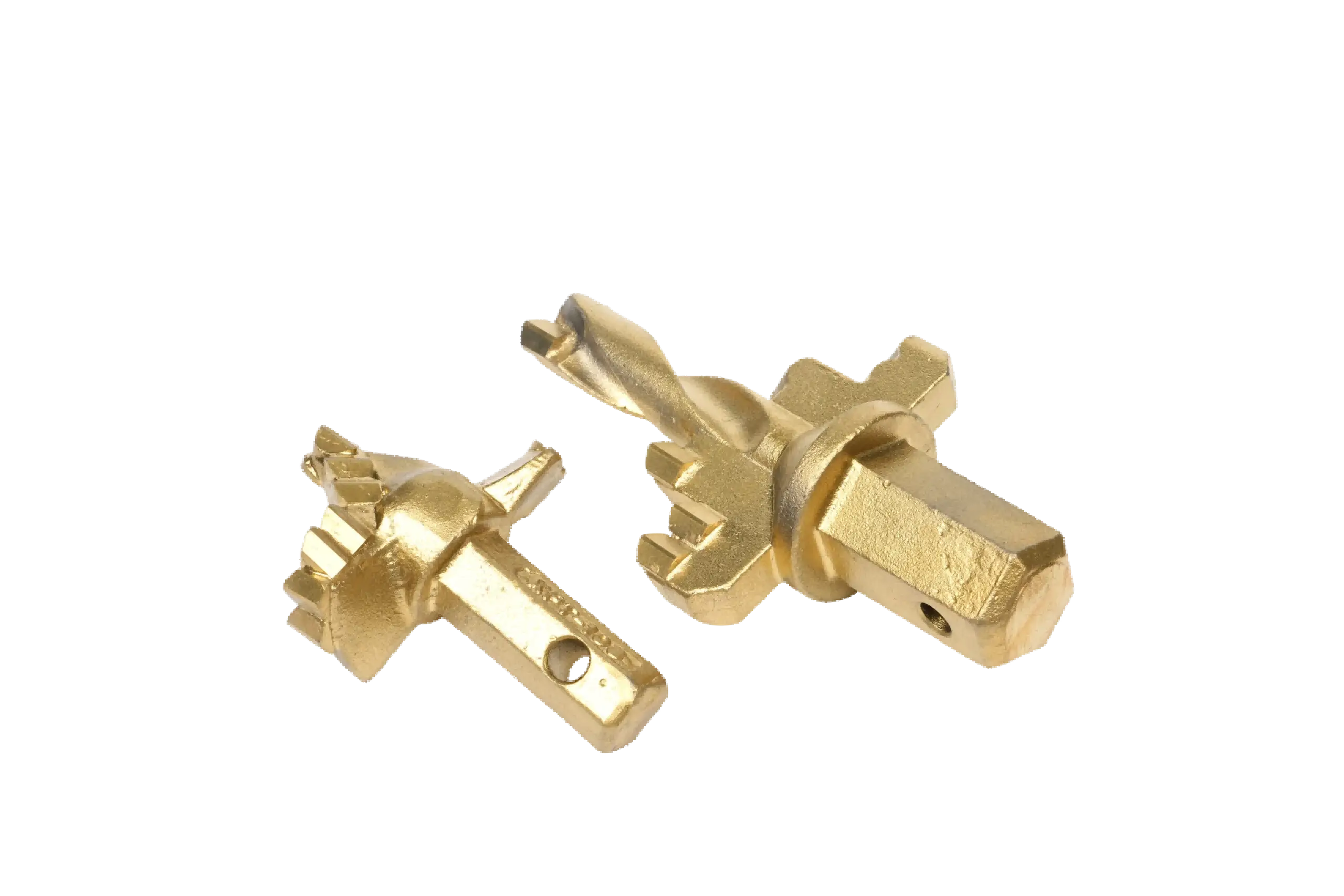

Stainless steel forgings are produced by applying pressure to the blank through a forging process, inducing plastic deformation, thereby improving its mechanical properties and forming a product with specific shapes and mechanical characteristics.

Product Advantages

Stainless steel forged parts can eliminate internal pores and cracks in the metal, significantly enhancing their mechanical properties. This product is widely used in various fields, such as manufacturing, military industry, pressure vessels, railway transportation, and power systems. It adjusts the shape, size, and microstructure of the metal blank through plastic deformation caused by compressive stress from forging hammers, presses, and other equipment during the forging process, to meet different application requirements.

Product Structure

1. Solid Forgings: These forgings are made from solid metal blocks and come in various shapes, ranging from basic geometric forms to complex structures, such as cylinders and cubes.

2. Hollow Forgings: In contrast to solid forgings, hollow forgings have a hollow structure inside, suitable for parts requiring weight reduction or internal passages, such as pipes or ring-shaped components.

3. Stepped Forgings: These forgings have different cross-sectional dimensions and are often used to connect parts of different diameters, such as shaft components.

4. Gear-shaped Forgings: Forgings with gear teeth shapes, suitable for manufacturing gears and other transmission components.

5. Flange-shaped Forgings: Forgings with flanges, used for pipe connections or as supporting structures.

6. Impeller-shaped Forgings: Suitable for manufacturing impellers for turbines, pumps, and other rotating equipment.

7. Crankshaft-shaped Forgings: Used in engines and other machinery, possessing complex shapes and multiple cranks.

8. Connecting Rod-shaped Forgings: Used to connect pistons and crankshafts, usually having complex shapes and specific dimensions.

9. Gear Shaft-shaped Forgings: Forgings combining gears and shafts, used to transmit torque and withstand bending loads.

10. Ring-shaped Forgings: Forgings with a ring structure, commonly used for bearing housings, seals, etc.

Stainless steel forgings achieve shape changes by forging metal blanks, thereby producing workpieces or preforms. This type of product boasts advantages such as high hardness, lightweight structure, strong resistance to impact and heavy loads, material savings, and excellent fatigue resistance.

Dongpei Forging Products Customization Scope:

1. Raw Materials: Forgings can be made from a variety of metal materials, such as carbon steel, alloy steel, stainless steel, copper alloys, aluminum alloys, titanium alloys, etc.

2. Shapes: Forgings come in a wide variety of shapes, such as round bars, squares, rings, gears, connecting rods, flanges, shaft components, blades, etc.

3. Dimensions: Forgings have a wide range of dimensions, from a few millimeters to several meters, depending on actual application requirements, specifically involving length, width, height, diameter, and thickness.

4. Weight: The weight of forgings ranges from a few grams to tens of tons, determined by their size and material density.

5. Precision Level: Based on differences in processing precision, forgings can be divided into different precision levels, such as ordinary grade and precision grade.

6. Surface Treatment: Various surface treatments can be applied to forgings, such as shot blasting, polishing, coating, heat treatment, etc., to suit different operating conditions.

7. Standards and Specifications: The production and manufacturing of forgings must comply with relevant national or international standards, such as GB (China), ASTM (USA), DIN (Germany), JIS (Japan), etc.

Given the wide variety of forgings available, please feel free to inquire if you have any needs. Whether you require unconventional, specialized requirements or pursue the ultimate in performance, Dongpei leverages its forging technology to provide tailored solutions. Choosing Dongpei ensures that every forging is precisely tailored to your production needs, providing a solid foundation for your product’s competitiveness.

Keywords:

stainless steel forging Manufacturers

stainless steel forging Suppliers China

Customized stainless steel forging