The following table summarizes the core differences between the two from key dimensions:

| Comparison Dimensions | Cold Forging Process | Hot Forging Process |

| Forming Temperature | Below the metal’s recrystallization temperature (typically room temperature) | Above the metal’s recrystallization temperature (800-1250°C for steel) |

| Forging Accuracy | High (tolerance ±0.03-±0.08mm) | Low (tolerance ±0.5-±1mm) |

| Surface Quality | Excellent (Ra 0.4-1.6μm, no oxidation) | Poor (Ra 6.3-25μm, with scale) |

| Mechanical Properties | High strength and hardness (work hardening) | Good toughness (grain refinement, requires heat treatment for strengthening) |

| Material Utilization | High (90%-95%) | Low (70%-80%, burnout + flash) |

| Material Adaptability | Narrow (low-hardness materials such as mild steel and pure aluminum) | Wide (all metals, including high-alloy steels and titanium alloys) |

| Equipment Cost | High (high-strength presses) | Low (forging hammers, standard hydraulic presses) |

| Mold Cost | High (wear-resistant materials + coatings) | Low (standard hot work die steels) |

| Applicable Part Types | Small, simple parts (bolts, bearing rings) | Large, complex parts (crankshafts, wind turbine main shafts) |

| Production Efficiency | High (100-300 pieces/minute, automated) | Low (10-50 parts/minute, long heating cycle) |

Process Selection Recommendations

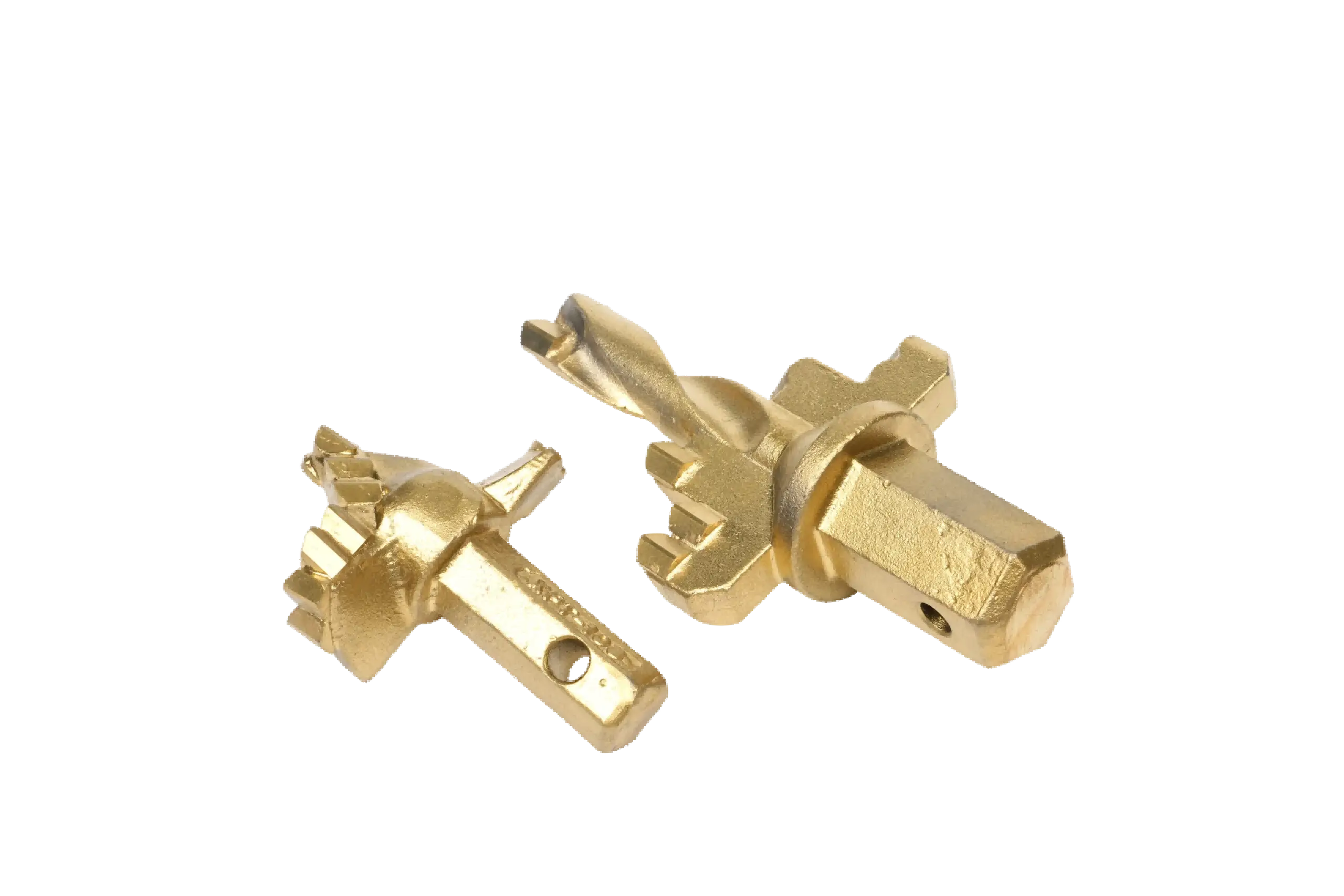

l Cold forging is preferred for small batches of parts requiring high precision, high surface quality, and high hardness, such as automotive fasteners (bolts and nuts), electronic connectors, and medical device parts.

l Hot forging is preferred for large, complex structures or components made of high-hardness materials, such as engineering machinery crankshafts, aircraft engine turbine disks, and wind turbine main shafts.

In summary, there is no absolute superiority or inferiority between cold forging and hot forging. The choice should be based on the required performance, size, material type, and production volume of the forging. Together, they cover the full range of metal plastic processing needs, from micro-precision parts to heavy structural components.