1. Definition and Application

Mining connectors are devices used to quickly and securely connect cables, pipes, or mechanical components between mining equipment. They must meet explosion-proof, waterproof, and tensile-resistant requirements. They are commonly found on equipment such as coal mining machines, conveyors, and hydraulic supports.

2. Main Types

Cable Connectors (such as mining explosion-proof plugs):

Used for power or signal transmission, with a locking mechanism to prevent detachment.

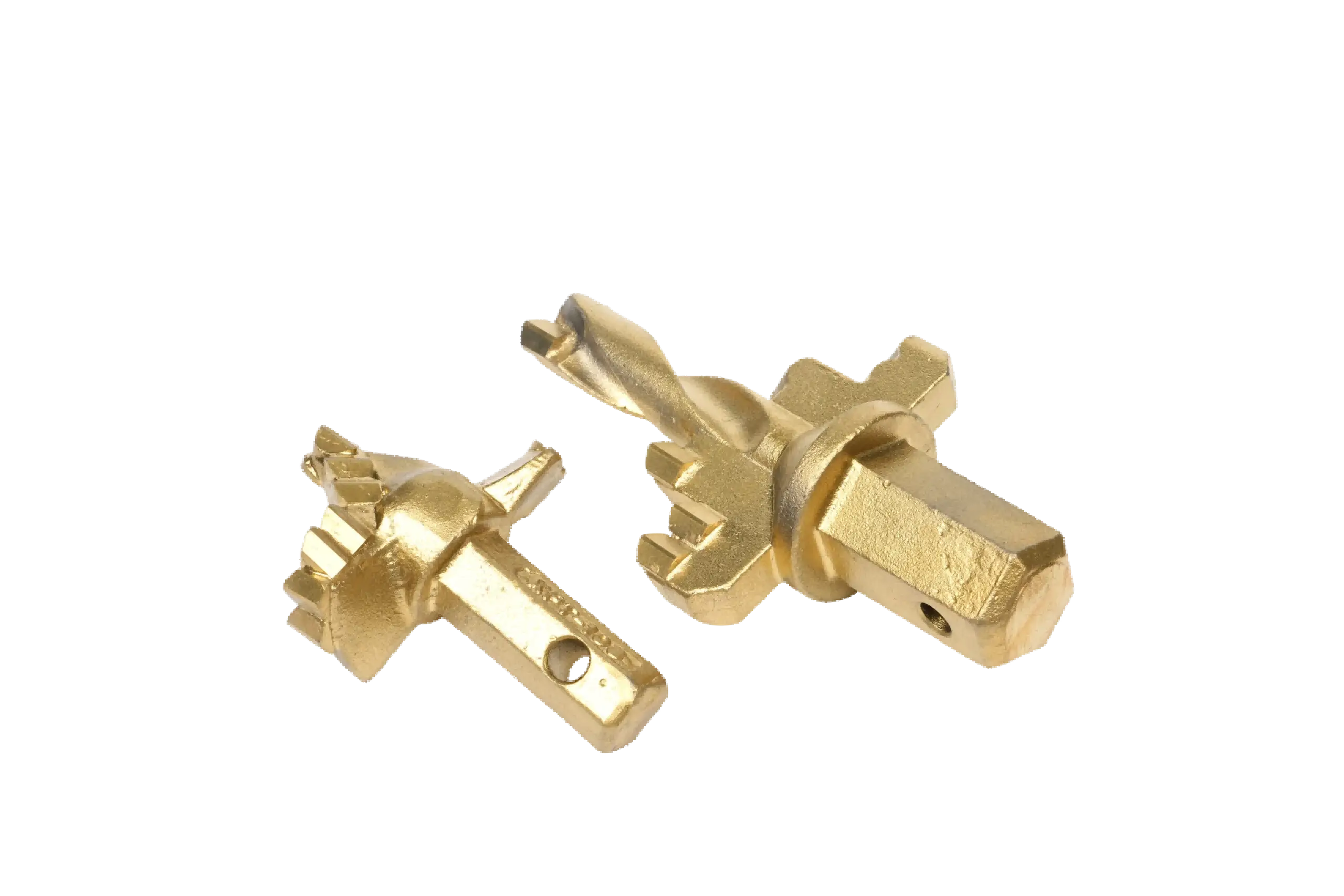

Hydraulic Quick Connectors:

Connect and disconnect hydraulic lines without tools, minimizing leaks.

Duct Connectors:

Used for compressed air pipelines, with a sealing ring to prevent leaks.

Mechanical Connectors:

Such as chains and pins, used to connect components in scraper conveyors.

3. Core Features

Explosion-proof Certification: Meets mining explosion-proof standards (such as Exd I).

Protection Rating: IP67 and above, waterproof and dustproof.

Durability: Metal materials (such as nickel-plated brass) are impact- and wear-resistant.

Quick Assembly and Disassembly: Some designs feature self-locking or snap-on design for improved efficiency.

4. Application Scenarios

Cable/hydraulic connections for fully mechanized mining face equipment (coal shearers, roadheaders);

Quick docking of underground drainage pipes;

Sealed connections for air ducts in ventilation systems.

5. Selection Key Points

Voltage/current ratings (cable connector);

Working pressure (hydraulic connector);

Ambient humidity and corrosiveness;

Requirement of shielding (signal transmission).

6. Special Mining Requirements

Safety Certification: Requires national mining product safety certification (MA/KC mark).

Easy Maintenance: Mining environments are harsh, and equipment must be easily repairable underground.

Standardization: Interface dimensions must conform to industry standards (such as GB/T 3836) to ensure interchangeability.