Impact of Excessively High Heating Temperatures:

1. This leads to coarse grains, reducing the strength, toughness, and fatigue resistance of the aluminum parts, which is difficult to fully improve through subsequent heat treatment.

2. It exacerbates surface oxidation and decarburization of the billet, forming a thicker oxide scale, increasing cleaning difficulty, and may also cause oxide inclusion defects.

3. Exceeding a certain temperature can cause the aluminum alloy to overheat, resulting in grain boundary melting and a loose microstructure, directly leading to billet scrap.

4. Some aluminum alloys may exhibit compositional segregation, affecting the overall performance uniformity. Furthermore, at high temperatures, the billet is prone to sticking to the mold, damaging the mold.

Impact of Excessively Low Heating Temperatures:

1. This results in insufficient plasticity of the aluminum alloy, significantly increasing deformation resistance, requiring higher forging pressure, and increasing equipment energy consumption and load.

2. Poor metal fluidity makes it difficult to fill the mold cavity, easily leading to forming defects such as insufficient material and unclear edges.

3. Significant stress concentration occurs during forging, easily causing cracks at corners and thin-walled areas, reducing product yield.

4. Uneven deformation leads to disordered internal microstructure in the forging, making it prone to performance fluctuations after subsequent machining.

How to Avoid Overheating or Underheating of Aluminum Alloy Billets?

Key Conclusion: Overheating or underheating can be effectively avoided by using precise temperature control equipment, standardizing process parameters, strengthening process monitoring, and optimizing operating procedures.

Select Precise Heating Equipment: Prioritize the use of equipment with high temperature control accuracy, such as medium-frequency induction furnaces and resistance furnaces. Temperature control errors can be controlled within ±5℃, avoiding temperature fluctuations associated with open flame heating.

Equipment should be equipped with an automatic temperature control system and alarm devices. Prompt alerts should be triggered when the temperature exceeds or falls below the target range to prevent human error.

Define and Strictly Implement Process Parameters: Develop specific heating specifications for each aluminum alloy grade, clearly defining the heating temperature range, heating rate, and holding time. For example, for 6061 aluminum alloy, the heating temperature is 370-450℃, and the heating rate should be controlled at 5-10℃/min.

The holding time should be adjusted according to the billet thickness, generally 1-3 min/mm, to ensure uniform internal temperature of the billet and avoid “external heat and internal cold” or “overheating and burning.”

Strengthen Heating Process Monitoring:Utilize thermocouples, infrared thermometers, and other tools to monitor the surface and internal temperature of the billet in real time, avoiding reliance solely on equipment temperature displays.

Regularly calibrate temperature measuring equipment to ensure data accuracy; weekly calibration is recommended to prevent instrument errors from causing temperature runaway.

Optimize Operation and Environmental Control:Clean the surface of the billet of oil and oxide scale before loading into the furnace to prevent impurities from burning and affecting temperature judgment. Simultaneously, arrange the billets properly to ensure uniform heating within the furnace.

Control the furnace atmosphere by using inert gas protection or sealed heating to reduce oxidation and prevent atmosphere fluctuations from indirectly affecting temperature stability.

Avoid prolonged residence of the billet in the furnace. Remove the billet from the furnace for forging promptly after heating to prevent overheating and excessive temperature.

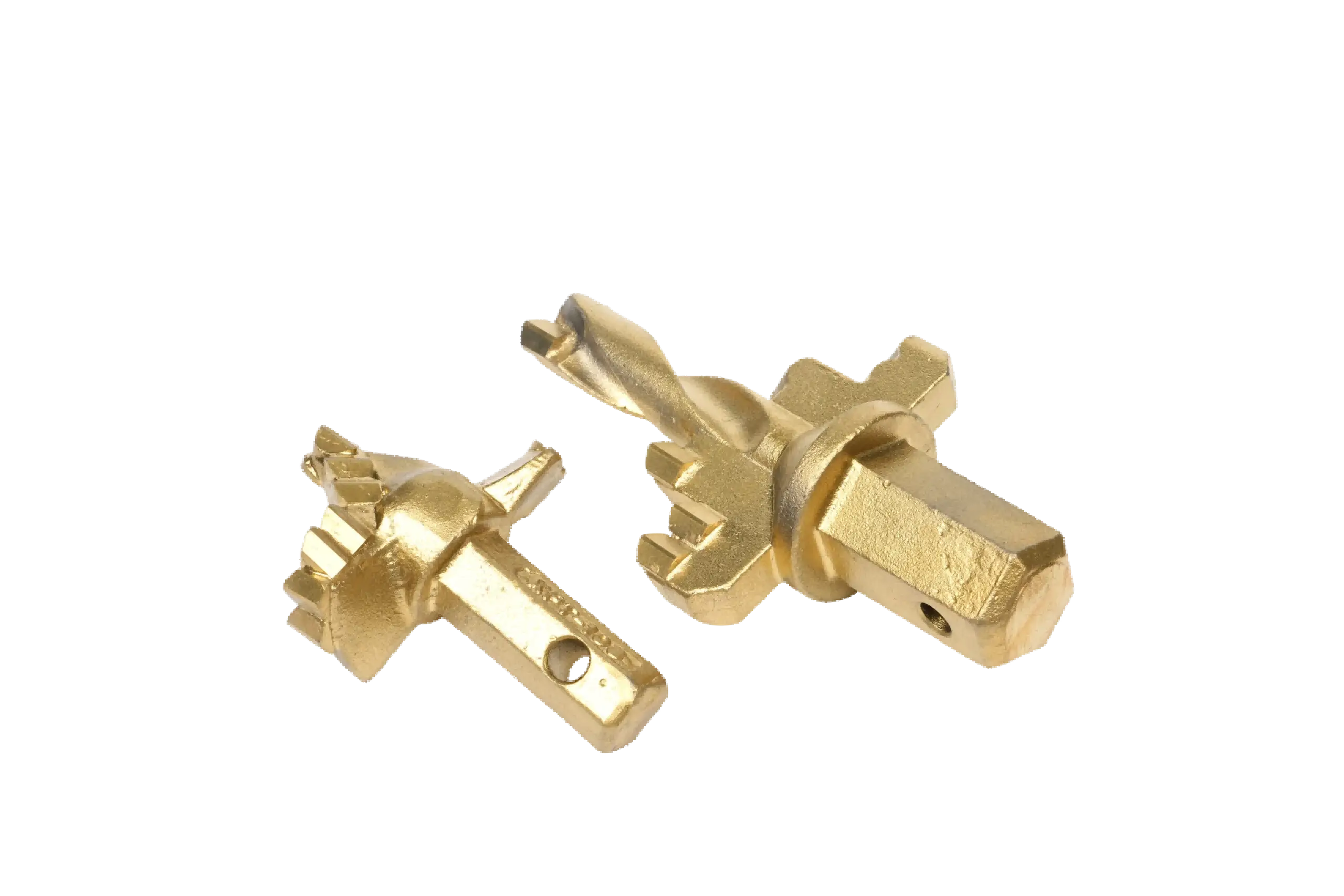

Forged Aluminum Parts Suppliers China: Dongpei Forging

In modern industry pursuing lightweight and high strength, aluminum alloy forgings are a key solution. They offer higher strength, better toughness, and longer service life than traditional parts.

Dongpei Forged Aluminum Parts Factory specializes in precision forging of aluminum parts, making us your reliable partner for customized aluminum alloy forgings. With advanced equipment and mature processes, we strictly control every step from raw materials to finished products, ensuring high precision and reliability.

We offer flexible customized aluminum parts services, producing high-quality forgings suitable for various industries such as automotive, machinery, and communications, based on your drawings or requirements.

Contact us for customized forged aluminum parts! Let us empower your products with our professional forging technology. Contact us today to get your customized solution.